Robot Calibration App Eases Complex Mold Design, Manufacture Constraints

SprutCAM X Robot programming software, aided by the free Robot Calibration mobile app, has expanded its list of supported robots and mechanisms, to accurately calibrate robot movement and tool operations.

An update to SprutCAM Tech’s free Robot Calibration mobile app application now supports robots from 14 leading industrial robot manufacturers. Industrial robots are particularly beneficial in industries that require the production of products and parts with complex surfaces, such as molds, as they are able to move the machining tool along six axes, while most advanced CNC machines can only move along a maximum of five axes. This is made more efficient and easier with SprutCAM X Robot programming software, ultimately easing mold design and manufacturing constraints.

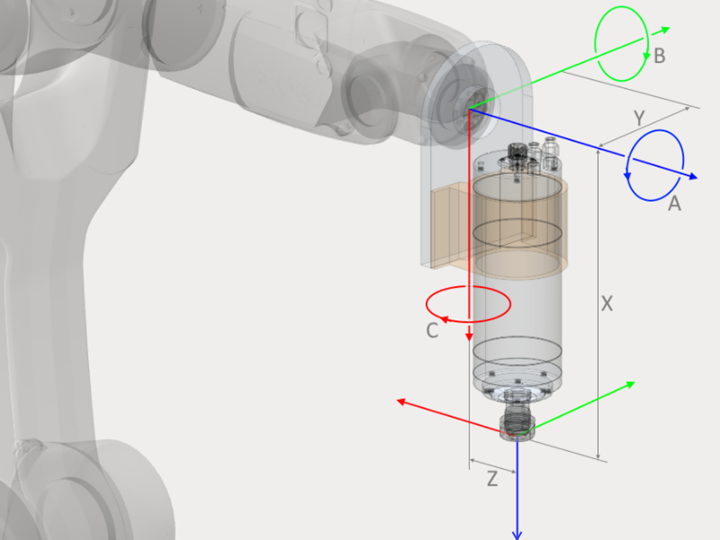

The mobile app is designed to accurately calibrate the Tool Center Point (TCP) and automatically transfer the data to SprutCAM X Robot via a smartphone. TCP calibration is a process used in robotics to determine the position of a tool relative to the robot’s arm or body. This information is critical to ensuring the accuracy of the robot’s movements and the precision of its tool operations. The goal of TCP calibration is to find the exact position of the tool tip, which can then be used as a reference point for the robot’s motion control system. This enables the robot to consistently and accurately perform tasks such as cutting, drilling and welding in the correct location.

SprutCAM Tech says the original application version only worked with the robots of three well-known manufacturers. The latest version, however, now supports TCP calibration for the following robot brands: FANUC, KUKA, CRP, Denso, Dobot, Estun, Hiwin, Hyundai, Motoman, Newker, Manutec, Nachi, OTC Daihen and Turin.

SprutCAM Tech’s app uses the double spikes method for calibration:

- Measurement of the position of the long tool. The position of the tool is measured at different joint angles or at different positions along the robot path.

- Measurement of the short tool position and automatic determination of the tool orientation.

- Automatic recognition with OCR and reading of the data by the Robot Calibration application and calculation of TCP coordinates.

- Transmission of TCP coordinates to MachineMaker using a QR code.

The double spikes method is a TCP calibration method used in robotic and machine tool applications. It consists of measuring two points on a probe and calculating the position of the tool center point based on these measurements. SprutCAM Tech says the double spikes method can be useful in situations where the probe is unable to measure the tool position at the exact TCP.

For SprutCAM X Robot software users, the Robot Calibration mobile app eliminates errors caused by manual data entry; reduces robot debugging time; removes the need for expensive calibration tools or services; and supports multiple robots and mechanisms.

The Robot Calibration can be downloaded for free from Google Play and Apple Store.

Related Content

-

Laser Welding Versus Micro Welding

The latest battle in finely detailed restoration/repair of mold materials.

-

Maintaining a Wire EDM Machine

To achieve the ultimate capability and level of productivity from your wire EDM on a consistent, repeatable and reliable basis, regular maintenance is a required task.

-

Hands-on Workshop Teaches Mold Maintenance Process

Intensive workshop teaches the process of mold maintenance to help put an end to the firefighting culture of many toolrooms.