Predictive Maintenance Monitoring System Contributes Real-Time Diagnostics

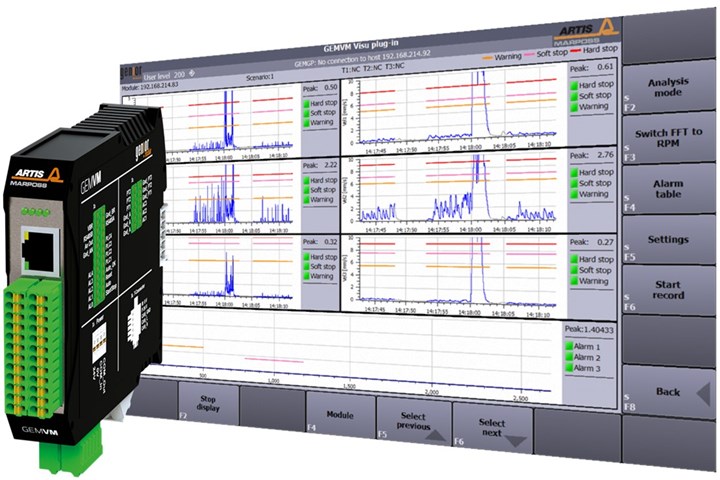

The Artis GEMVM system from Marposs features predictive maintenance to monitor vibration, gravity and temperature values to detect machining anomalies.

Photo Credit: Marposs

With the ability to be integrated into Marposs’s Genior modular monitoring system, the company’s new Artis GEMVM system is said to be a highly effective solution for predictive maintenance, simple process monitoring and detection of collisions and crashes. The system monitors vibration, gravity and temperature values to detect machining anomalies, such as damage to spindle bearings or wear of the drive axles. When a sudden change occurs, the system initiates an alarm in less than 1 ms, reducing or avoiding the downtime and costs of unplanned maintenance or total failure of machine components.

According to Marposs, the use of predictive maintenance, in this case, is a more advanced option than preventative maintenance, contributing real-time information from the machine tool to avoid unwanted future events and prevent early or late replacements.

The GEMVM system measures acceleration in up to three axes (depending upon sensor type) with a measuring frequency of up to 5.6kHz and a sampling rate of 25kHz. It has eight definable and selectable operating modes with five freely activatable static alarms. Events that violate the predefined hard stop limits are logged in the event memory with relevant information for later analysis.

The system comes with the Artis VisuScope diagnostic tool, which Marposs contends is ideal for assuring the quality of new machines and those in operation. Process analyses based upon determined GEMVM data allow historical comparison of machine states, evaluation of damages, and the control after repairs.

The GEMVM can function in a stand-alone mode, running on Windows (WIN 7/10) machine control panels or Siemens Linux systems (TCU). The software can also be installed on 7 or 10-inch industrial PCs from Marposs or any Windows PC (WIN 7/10). Additionally, the GEMVM can also be integrated into a Genior modular monitoring system for process monitoring purposes, delivering the vibration velocity and acceleration to a processing unit for further evaluation.

Related Content

-

Questions and Considerations Before Sending Your Mold Out for Service

Communication is essential for proper polishing, hot runner manifold cleaning, mold repair, laser engraving and laser welding services.

-

What Is Scientific Maintenance? Part 1

Part one of this three-part series explains how to create a scientific maintenance plan based on a toolroom’s current data collection and usage.

-

5 Hot Runner Tips for Moldmakers and Molders

Best practices for initial hot runner tryouts and effective preventive maintenance.