Positive Wiper Geometries Increase Productivity, Part Quality

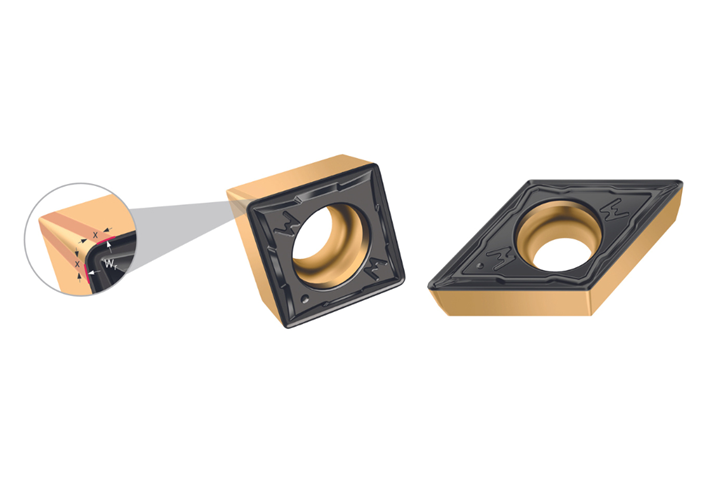

The curved wiper cutting edge featured on the universal FW4 and MW4 indexable insert geometries offered by Walter USA is capable of reducing machining time, increasing feed rates and doubling part surface quality.

With the FW4 and MW4 positive wiper geometries, Walter USA is introducing two indexable insert geometries for longitudinal turning and facing that combine the “wiper effect” and the new highly wear-resistant Walter Tiger·tec Gold grades.

The curved wiper cutting edge is a feature that makes the wiper action universal across various material groups such as steels, stainless steels, cast irons or even super alloys. The wiper action can be used to reduce machining time by using double the feed rate, while imparting the same surface finish. In some cases, feed rate increases of up to 300% were successfully utilized. A higher feed reduces the amount of time an insert stays in cut, reducing the friction and temperatures seen by the insert, extending tool life and reducing indexing times. Alternatively, an end user can double the surface quality while maintaining the same feed, which is the traditional use of wiper inserts.

The FW4 universal wiper geometry with a narrow chip breaker, which generates short chips, is for finishing operations. The machining parameters for the FW4 geometry are a feed of 0.0012-0.020" and a cutting depth of 0.004-0.100". The primary application is turning steel, stainless steel and cast iron (ISO P, M and K workpiece groups), and the secondary application is turning super alloys (ISO S workpiece group).

The MW4 universal wiper geometry with an open chip breaker groove and longer radius wiper cutting edge for high feeds is for medium machining. Machining parameters are a feed of 0.005-0.022" and a cutting depth of 0.020-0.180". The primary application is turning steel and cast iron (ISO P and K workpiece groups), and the secondary application is turning stainless steel and super alloys (ISO M and S workpiece groups).

Related Content

-

3D Printing Enables Better Coolant Delivery in Milling Operations

Just like 3D printing enabled conformal cooling channels in molds, additive manufacturing is now being used to optimize coolant delivery in cutting tools.

-

Ten Things You Need to Know about Circle Segment Milling

Considerations for evaluating if circle segment end mills or conical barrel cutters are right for your mold machining applications.

-

How a Small Programming Change Cuts Cycle Time in Half

Overriding the CAM system when milling a series of lifter pockets helps to improve metal removal rate and increase feed rates.