New Steel Headquarters Facilitate Faster Lead Times

National Tool & Manufacturing Co. relocated its steel headquarters to East Dundee, Illinois. The company says the move facilitates a number of benefits.

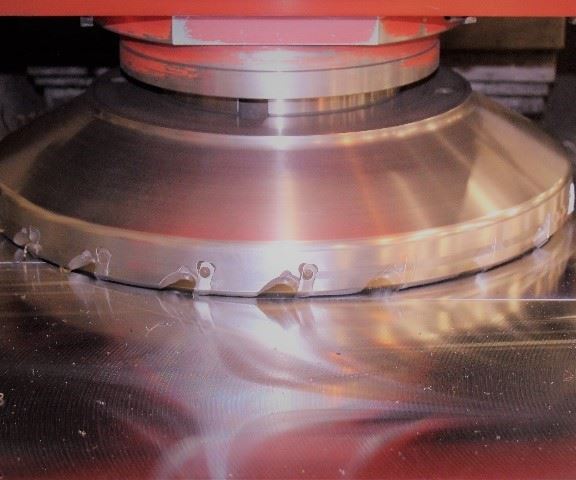

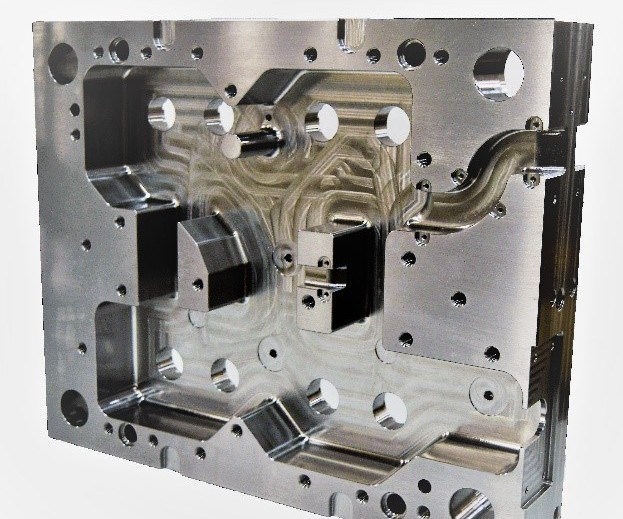

National Tool & Manufacturing Co. (NTM) has expanded operations to respond to customers "quick-to-market" strategies. NTM relocated its steel headquarters to East Dundee, Illinois, in 2018. The company says that the East Dundee location is designed for ideal material handling, storage and production flow as well as for expanded lifting capabilities. NTM says that the move further improves NTM's lead times on processed mold base plates and improves sawing, milling and grinding on both raw and processed mold plates.

The East Dundee steel facility upgrades follow the 2016 expansion of NTM's temperature controlled mold base manufacturing plant. According to NTM, the dedicated machining facility with internal precision grinding capabilities enable premium, "insert-ready" mold-base construction. NTM says that the combined steel service center and mold base manufacturing operation offer a "one-stop" supplier for every size mold builder.

Related Content

-

How to Lower Cycle Times With the Right Tool Steel

Combining excellent mechanical properties, high wear resistance and high thermal conductivity in a specialty tool steel yields cycle time reduction.

-

Micro-Milled Steel Plate Cuts Mold Build Times by 10-15%

Steel 21 emphasizes its tighter tolerances, improved surface quality and speed of processing using the patented “21 Micro Milling” process.

-

Coating Technology Enables Tough Mold and Die Steel Machining

Millstar, a part of Cole Tooling Systems, presents a multi-layer hybrid nanocoating for cutting tools that provide key benefits for increased efficiency in any machining operation.