New Mini Mold Components

At Fakuma, Meusburger went “small” with its two newest standard mold components.

Meusburger (U.S. office in Charlotte, N.C.) says its E 3310 TT-Slide unit is said to be the “smallest ready-to-use slide unit on the market.” It’s available with slide surfaces of 12 by 10 mm and 15 by 12 mm. CAD data is available for download. The “TT” designation refers to the T-guides in the slide and cotter. This type of guide is said to guarantee optimal force transmission at high injection pressures through surface contact. The DLC coating on steel of 52 HRC offers both high wear resistance and easy sliding properties. The slide is also said to be suitable for mirror polishing. The supplied buffer stops the small slide safely and precisely, even at high speed.

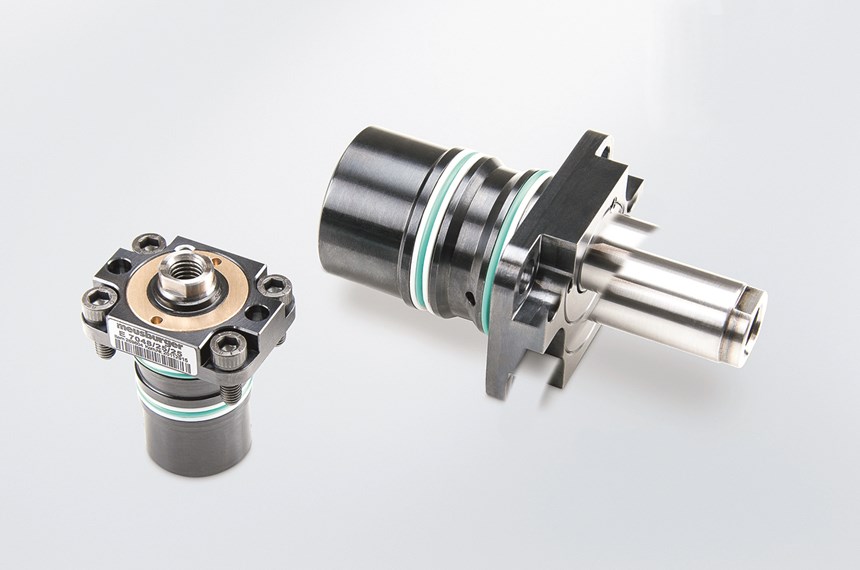

This function can be implemented directly in the tooling insert or in the cavity plate to save space. The slide and guide can be installed and removed together. Second, Meusburger introduced the E 7048 “build-in” cylinder with flange (above), said to be suited to the smallest installation spaces. It comes in four sizes with three different strokes each. The smallest flange size is 37 by 25 mm. Surface or flush installation is possible. Double-sealed piston rods with additional rod wipers ensure clean operation, and the Viton FKM seals can withstand temperatures up to 180 C/356 F. The cylinder can be removed quickly and easily by means of a pull-off thread.

Related Content

-

Revisiting Some Hot Runner Fundamentals

What exactly does a hot runner do? If you’ve been in the injection molding industry for any length of time, you might think the answer is obvious, but it is not.

-

Machine Hammer Peening Automates Mold Polishing

A polishing automation solution eliminates hand work, accelerates milling operations and controls surface geometries.

-

Hands-on Workshop Teaches Mold Maintenance Process

Intensive workshop teaches the process of mold maintenance to help put an end to the firefighting culture of many toolrooms.