Moldmaking Strategies Take on Surface Finish, Accuracy and Short Delivery Time Challenges

SolidCAM combines high-quality toolpath fidelity, surface finish, automatic toolpath updates and error-free G-Code for an ideal CAM solution.

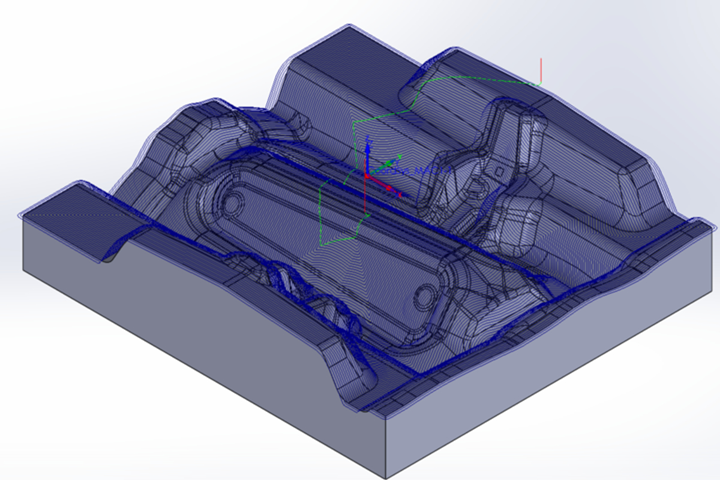

Photo Credit: SolidCAM

SolidCAM highlights its Integrated Solution, along with iMachining, as an ideal CAM solution for moldmaking.

According to the company, the main challenges for the industry are surface finish, surface accuracy and short delivery times. To meet these challenges, SolidCAM reportedly combines:

- Excellent toolpath quality/fidelity by working directly on the CAD model

- High-quality surface finish, and hard-material cutting performance from optimally controlled cutter-to-material contact

- The time-saving benefit of automatic toolpath updates for mold changes

- Error-free G-Code and the elimination of on-machine edits for first part success

SolidCAM notes its latest version also included enhancements to its iMachining 3D, HSM and simultaneous five-axis modules which combine mold and insert machining.

Related Content

-

U.S. Economy Indicates Prospects for Moldmakers

An examination of the U.S. economy suggests its resilience against a recession, yet a mixed outlook for moldmaking and plastics persists.

-

Reshoring Initiative Reports Another Stellar Year

According to the report, the IRA and Chips Act combined with deglobalization trends to boost reshoring in 2022 to another all-time high — up 53% from 2021’s record.

-

How to Supply Cooling to Additive Tooling

Additive tooling provides limitless options for cooling a mold’s difficult-to-cool areas.