Molder Emphasizes Circularity in Molding, Extrusion, Automation and AM

NPE2024: Alongside partners, KraussMaffei provides a comprehensive look at its offerings — from injection molding machines to automation and additive manufacturing — as well as partnerships, to advance its focus on sustainability.

KraussMaffei comes to NPE2024 with the motto “Make plastic green — with high quality and efficiency.” This is exemplified through injection molding, extrusion, reaction process machinery, automation and additive manufacturing focusing on the circular economy and reducing the CO2 footprint.

The company notes that all injection molding machines at the booth are connected to socialProduction via the KraussMaffei smartCube. The socialProduction product family enables intuitive monitoring of the injection molding machines, the production process and the condition of the machine components.

ProductionMonitor, for example, provides a quick overview of the machinery and helps to efficiently monitor each connected machine with intelligent production key figures. With processSupport, the process is monitored autonomously using artificial intelligence. The early detection of deviations and proactive communication to the operator increase efficiency.

The liveCare condition monitoring solution offers continuous online monitoring of the condition of the machine components. This enables the implementation of condition-based maintenance strategies. EnergyControl ensures that energy consumption is optimized. The module provides a detailed insight into the total energy consumption of the injection molding machine and the individual machine components, including energy-related CO2 emissions.

Material cycle

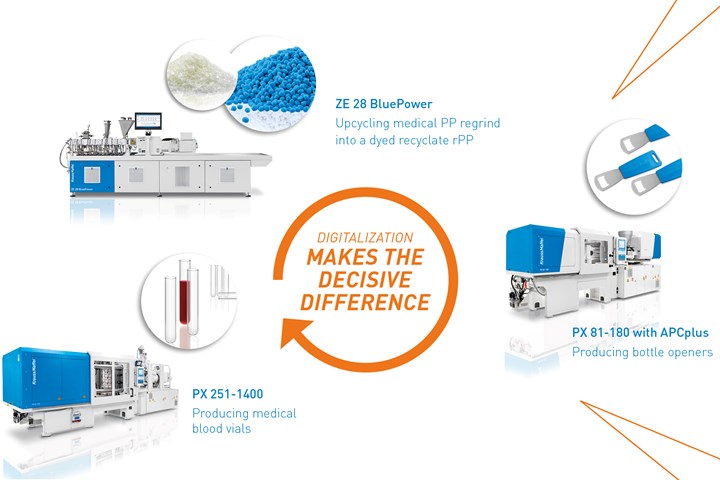

Visitors can experience the entire material cycle, from a short-live medical blood vial to a long-live bottle opener, at the KraussMaffei booth. Starting with injection molding on a PX 251-1400, moving on to the upcycling process and the twin-screw extruder ZE 28 BluePower and then to the all-electric injection molding machine PX 81-180, KraussMaffei demonstrates everything from valuable utilization of raw materials from disposable articles to production of premium quality components with a long service life.

The all-electric PX 251-1400 produces 32 medical blood vials per shot from PP 9074 MED material supplied by ExxonMobil. After shredding, these vials serve as base material for the upcycling process carried out on the ZE 28 BluePower twin-screw extruder. Here, various additives such as bonding agents and liquid pigments are added, mixed and homogenized. The resulting recompound is transferred to the downstream injection molding machine — more precisely to the an all-electric PX 81-180.

As recyclates can cause significant process fluctuations due to different viscosities, the PX 81-180 is equipped with APCplus. This machine function reliably compensates for these fluctuations. This enables components to be produced with consistently high quality with scrap reduced to a minimum.

Direct compounding injection molding (DCIM)

Another form of sustainable solutions is shown by the direct compounding injection molding (DCIM) process, with which the company says up to 50% of material costs can be saved, also giving the processor considerably more freedom and control in the development of formulas. For DCIM, a single-screw extruder is installed in a space-saving piggyback position directly over the injection unit of a standard hydraulic machine.

The compounded melt is conveyed into the plasticizing unit in a single heating process, which reduces degradation of the polymer. In addition, the one-step process conserves energy and reduces the CO2 footprint. At NPE, a GX 1100-4300 DCIM produces rugged, reusable crates made of three different recycled materials.

The smartOperation machine function enables easy startup and control of the injection molding machine. This not only enables defect-free machine operation but also increases process stability and thus boosts efficiency in production.

MuCell screw

According to KraussMaffei, MuCell can do everything that’s currently in demand — generate savings on material, energy and investment costs — and thus reduce the CO2 footprint of products. KraussMaffei is highlighting its new universal screw for MuCell applications with 30% higher plasticizing performance.

The new HPS-Physical Foaming screw has a longer three-zone area, which can be universally used for all plastics (with and without fiber reinforcement) and has a plasticizing capacity that has increased by up to 30%. This allows for the selection of lesser screw diameters than before, which can reduce investment and operating costs for the plasticizing unit, or for the generation of a greater output using a screw of the same size as before.

PX 121-180 SilcoSet

Silicones, and particularly the new generations of liquid silicone rubber (LSR), continue to conquer new application areas thanks to their physical property patterns. At the same time, however, they burden the processor with challenges when it comes to precision and process consistency in the injection molding process. At NPE, a PX 121-180 SilcoSet produces matrix lenses for the headlight industry.

The APCplus machine function supports sustainable production by continuously analyzing the injection molding process and quickly and accurately compensating for material- and environment-related fluctuations in melt viscosity. This ensures a consistently high component quality and thus minimum scrap.

The two-cavity LSR matrix mold comes from mold specialist ACH Solution, providing optimal temperature balancing even with longer scheduled downtimes. The ACH Servoshot 2G stands for precise needle valve regulation. The linear robot LRX 150 from KraussMaffei with EOT from ACH Solution allows an inline production with inspections, weight check and separation.

Partnership with NIAR

Another highlight is the manufacturing demonstrator, Frankenstein, from the National Institute for Aviation Research (NIAR) at Wichita State University. It showcases different examples of how to introduce automotive-matured ultra-high-rate manufacturing technologies to aerospace — a joint research program NIAR and KraussMaffei are driving forward with together.

In addition, NIAR is showing the inlet duct of a 10-meter-long unmanned system manufactured using a proprietary meltable tooling concept developed by Fiber Dynamics. A further highlight is an aircraft window plug that is currently undergoing certification efforts for aircraft passenger-to-cargo conversion activities at NIAR.

These composites parts are manufactured using the FiberForm technology developed by KraussMaffei. The process combines the thermoforming of organic sheets and injection molding in a single process. The result is lightweight fiber-reinforced plastic components with a high level of strength. Until now, they have mainly been used in the automotive industry. The cooperation between NIAR and KraussMaffei has now paved the way for FiberForm to be used in aerospace applications as well.

Clemson University driverless concept vehicle

Another partner at the KraussMaffei booth is Clemson University, showcasing its advanced materials and manufacturing expertise via multiple projects in mobility industries. Particularly highlighted is an ultra-efficient driverless concept vehicle designed for 2035.

Clemson students and faculty worked with ExxonMobil Chemical and Honda North America to engineer, build and validate the prototype with a focus on sustainability, resulting in a design with 18% plastics and composites by weight — nearly double the 10% market average. Built with reclaimed, lightweight and recyclable advanced materials, the project exemplifies the highly translational and rapid R&D engineering possible at Clemson.

U.S. HP-RTM bike

TIME Bicycles, in partnership with KraussMaffei, Fraunhofer USA and Clemson University, is raising the bar of composite bicycle technology through a development project to introduce high-pressure resin transfer molding (HP-RTM) to the cycling industry. Being showcased is a U.S.-produced HP-RTM bike. Visitors have the chance to register for a giveaway from first production. Retail value of the complete bicycle is $8,000.

U.S. market debut of additive manufacturing solutions

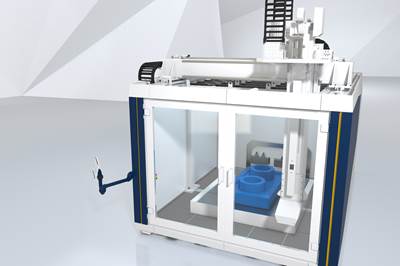

KraussMaffei says it has achieved a significant milestone by successfully introducing its additive manufacturing (AM) solutions and services in the EMEA market. Starting in the second half of the year, these industrial AM systems will also be available for the U.S. market. A key component of this offering is the innovative large-scale AM system, powerPrint, alongside the precisionPrint stereolithography system.

At NPE, KraussMaffei is touching on current case studies and solutions that illustrate the capabilities of powerPrint. The powerPrint excels in processing large parts while leveraging the advantages of 3D printing. With the capability to produce fully or partially filled structures, achieve a build volume of up to 10 m³ and simplify the implementation of complex designs, powerPrint presents an alternative to conventional production methods across various industries and applications.

Additional partners at the KraussMaffei booth are as follows: Audia Plastics, Basell Polyolefine, Big Spielwarenfabrik, Brabender, Bunting-Newton, BYK-Chemie, ColorLite, ConAir, Dow, Econ, Hekuma, iNOEX, Kärntner Montanindustrie, Kongsklide, motan, Open X, Prospect Group, Repi, S.C.S Societa Construzione Stampi, Sikora, Stäubli, technotrans, Trexel, vasantha group and Vision.

Related Content

VIDEO: Why Is Sustainability Important to Mold Builders

Marta Orozco with DME shares ways mold builders can be a part of building a more sustainable future.

Read MoreMMT Chats: Injection Molds and Integrated Solutions Through Ambition and Innovation

Jordan Robertson, VP, Business Development and Marketing for StackTeck discusses various mold technologies to improve efficiencies in automation, cooling, lightweighting and sustainability.

Read MoreHow to Solve Hot Runner Challenges When Molding with Bioresins

A review of the considerations and adaptations required to design hot runners and implement highly productive injection molding operations.

Read MoreAdvancing Moldmaking and Plastics: Trends in 3D Printing, Automation and Sustainability

NPE 2024 showcased the latest trends and technologies in innovation, efficiency and sustainability for moldmakers and molders, featuring advancements in 3D printing, automation, design and virtual reality/augmented reality/artificial intelligence.

Read MoreRead Next

KraussMaffei Extends Focus to Large-Scale, Sustainable Additive Manufacturing

Company adds large-scale, sustainable additive manufacturing to its portfolio of sustainable solutions for the plastics industry.

Read MoreLarge-Scale 3D Printer, Print-on-Demand Services

PowerPrint is KraussMaffei’s latest launch in the additive manufacturing space that is maximizing design freedom and cost efficiency. It is available for purchase or serviced through the company.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read More