Large-Scale 3D Printer, Print-on-Demand Services

PowerPrint is KraussMaffei’s latest launch in the additive manufacturing space that is maximizing design freedom and cost efficiency. It is available for purchase or serviced through the company.

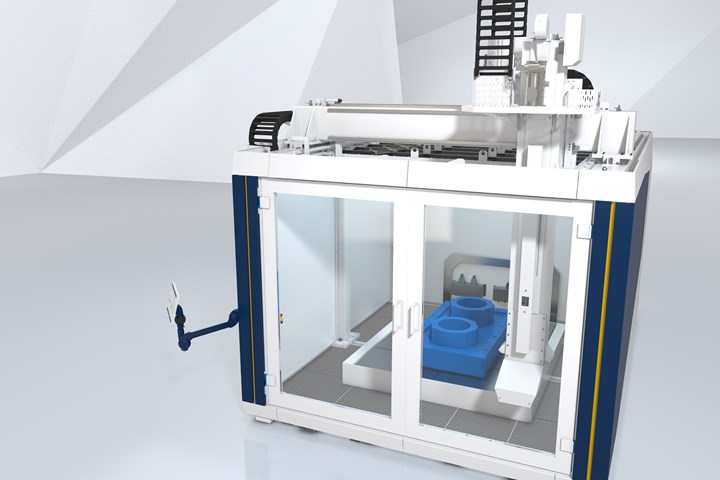

KraussMaffei’s large-scale 3D printer, powerPrint, which is capable of printing components up to 2 × 2.5 × 2 in size, is now available for purchase. Alternately, KraussMaffei offers a print-on-demand service.

The powerPrint large-scale printer is said to open up new fields of application for additive manufacturing. It is suitable for all industries that require large-format objects with consistently high product quality, such as tool and moldmakers, packaging and logistics and the automotive industry. According to Rolf Mack, vice president of additive manufacturing, “the powerPrint is ready to produce custom parts for the customer at the customer’s facility with the highest industry and quality standards.”

The powerPrint offers a high output rate (up to 30 kg/h) with high product quality, KraussMaffei reports. It is capable of producing components independently and without manual intervention at a temperature of up to 350°C. Parts are removed from the machine from the front through a door or by crane via a folding roof in the heat-resistant enclosure. Print jobs can be changed quickly thanks to vacuum-fixed printing plates. A specially developed HMI ensures intuitive and simple operation of the device, while ensuring a high level of work safety.

KraussMaffei also offers a print-on-demand service as an alternative to purchase. In this service, applications are designed according to customer specifications and technical possibilities and then printed, with KraussMaffei also handling post-processing. The powerPrint has already implemented several components in this way, such as a molding tool for the vacuum infusion process, a sand casting mold and a charging column, among others.

Related Content

-

MMT Chats: 4 Keys to a Successful Mold-Building Operation: Innovation, Transparency, Accessibility and Relationship

MoldMaking Technology Editorial Director Christina Fuges chats with Steve Michon, co-owner of Zero Tolerance in Clinton Township, Michigan, about the excitement of solving problems, the benefits of showing gratitude, the real struggle with delegation and the importance of staying on top of technology. This episode is brought to you by ISCAR with New Ideas for Machining Intelligently.

-

How to Supply Cooling to Additive Tooling

Additive tooling provides limitless options for cooling a mold’s difficult-to-cool areas.

-

In "Hybrid" FIM Process, 3D Printing Complements Injection Molding

Alpine Advanced Materials used a desktop 3D printer and the freeform injection molding process to reduce prototype tooling production time and cost for its customers.

.jpg;maxWidth=300;quality=90)