Software Simulation Eases Design Challenges for Moldmakers

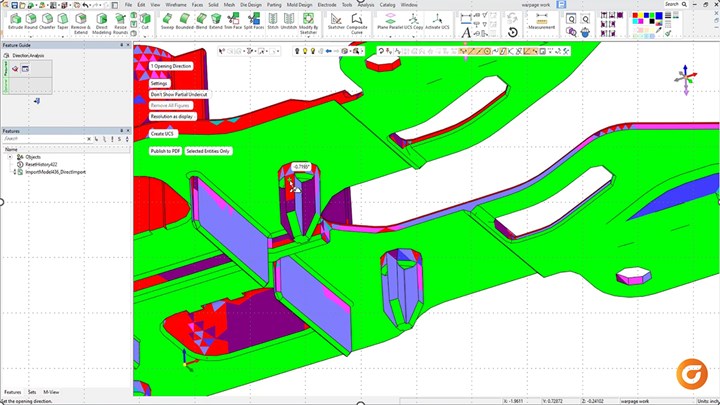

Cimatron’s integrated CAD/CAM interface is designed to systematically follow the mold design process from quoting to manufacture and provide complete workflow visibility.

Cimatron provides toolmakers with an integrated CAD/CAM solution for the design and manufacture of plastic injection molds and sheet metal stamping dies, as well as programming 2D to five-axis milling CNC machines. Cimatron is a single-source solution with a single, intuitive, easy-to-use interface for a shop’s entire workflow — from quoting, to design, to manufacturing (learn more about its version 16 release).

The Cimatron interface is designed to systematically follow the mold design process from sketch to CAD model to CAD programming to CNC G-code. Following this step-by-step process reduces guesswork and potential problems, and promotes good design. Cimatron part simulation offers a wide array of relevant information and complete visibility of the part and corresponding mold cavity.

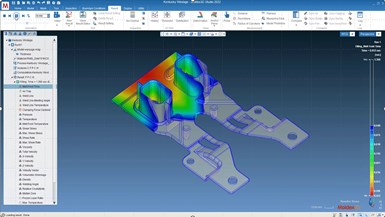

One such example of the power of part simulation is in designing mold parts to avoid warping. Warping is a common challenge in the plastic injection molding process. A dual software solution from Cimatron and Moldex3D uses accurate data and 3D simulation to forecast the amount of distortion that will occur before any mold core is machined. Moldex3D simulates a visual display of temperature ranges across the part, analyzes the data for warpage and exports the data as an STL model. Cimatron applies that data to the CAD file and enables the programmer to fine-tune part geometry and arrive at a workable CAD file from which to create the mold. In addition, Cimatron says it offers powerful simulation options and sectional views to control every detail of wall thickness and potential shrinkage.

A recent joint webinar from Cimatron and Moldex3D shows the process in more detail, including analyzing the part for warpage, capturing the results as a model and reversing the affects of the warpage on a CAD model.

Related Content

-

Mold Design Review: The Complete Checklist

Gerardo (Jerry) Miranda III, former global tooling manager for Oakley sunglasses, reshares his complete mold design checklist, an essential part of the product time and cost-to-market process.

-

It Starts With the Part: A Plastic Part Checklist Ensures Good Mold Design

All successful mold build projects start with examining the part to be molded to ensure it is moldable and will meet the customers' production objectives.

-

How to Improve Your Current Efficiency Rate

An alternative approach to taking on more EDM-intensive work when technology and personnel investment is not an option.