Compact Slides Provide Option for Difficult-to-Cool Locations in Molds

CUMSA introduces a new cooling system feature to its compact slides lineup to remove heat during the molding process.

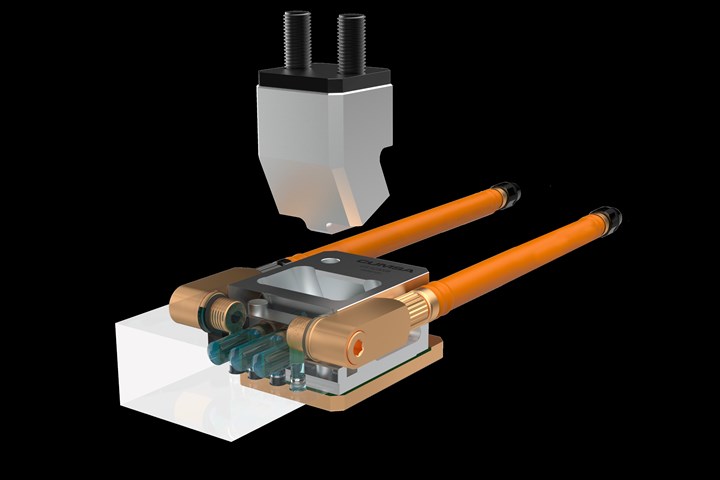

Targeting the challenges behind removing heat during the molding process, CUMSA USA introduces a new feature to its compact slides (part number CS) with a floating insert. The enhanced mold component, the CR cooled compact slide, provides an option to include cooling systems for difficult-to-cool locations, eliminating the need for a high precision pocket.

Available in three standard sizes, the CR includes an insert with pre-drilled holes. The holes are designed to make it easier to finish the cooling circuit once the insert detail is machined. The insert also has a 1/8 gas threaded hole on each side to connect the cooling hoses (MR sold separately) directly to the waterlines. The CR42 model offers three pre-drilled holes, the CR52 four pre-drilled holes and the larger model, the CR62, has five pre-drilled holes.

With this addition, CUMSA delivers an effective cooling system to optimize the molding process, lower cycle times, decrease energy consumption and improve plastic part quality. CUMSA also cites ease of installation and simple maintenance.

Related Content

-

6 Ways to Optimize High-Feed Milling

High-feed milling can significantly outweigh potential reliability challenges. Consider these six strategies in order to make high-feed milling successful for your business.

-

Moldmakers Deserve a Total Production Solution

Stability, spindle speed and software are essential consideration for your moldmaking machine tool.

-

Solving Mold Alignment Problems with the Right Alignment Lock

Correct alignment lock selection can reduce maintenance costs and molding downtime, as well as increase part quality over the mold’s entire life.