Stainless Steel Enables 3D Printing of Precision Tooling

IMTS 2024: Mantle’s 420 Stainless Steel allows manufacturers to rapidly produce production-grade tooling during prototyping and product development.

Mantle has announced the release of its 420 Stainless Steel material. This material addition improves toolmaking processes, enhancing speed and efficiency while reducing labor requirements, which is beneficial in industries such as medical that require corrosion-resistant tooling.

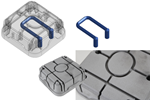

Mantle’s 420 Stainless Steel is chemically equivalent to traditional 420 stainless steel, which is known for its high strength, hardness, corrosion resistance and polishability. It is mold material well suited for a wide range of tooling applications, including components with conformal cooling and medical device tooling, Mantle’s 420 Stainless Steel allows manufacturers to rapidly produce production-grade tooling during prototyping and product development, which shortens the time to produce steel tooling for validation part molding by as much as 80%, according to the company.

Mantle’s 420 Stainless Steel is especially beneficial for tooling applications that employ conformal cooling channels. These channels enable more efficient cooling than traditional cooling methods, improving molding performance and reducing cycle times. Mantle’s 420 Stainless Steel has excellent corrosion resistance and eliminates the concern of conformal cooling channels clogging due to rust.

Mantle’s precision metal 3D printing technology can be used for printing precision tooling, meeting industry requirements for accuracy, surface finish and tool steel properties. Mantle’s 420 Stainless Steel is the next material in its family of Flowable Metal Pastes, which are precisely tuned to produce accuracy and surface finish. Mantle’s 420 Stainless Steel requires no modifications to toolmaking workflows for secondary operations such as texturing, polishing, welding and machining.

Related Content

-

How to Use Thermal Management to Improve Mold Cooling

A review of common mold cooling issues and possible solutions, including 3D printing applications.

-

How to Supply Cooling to Additive Tooling

Additive tooling provides limitless options for cooling a mold’s difficult-to-cool areas.

-

Precision Meets Innovation at IMTS 2024

After attending IMTS, it's clear that the integration of advanced technologies is ready to enhance precision, efficiency and automation in mold manufacturing processes. It’s a massive event, so here’s a glimpse of what the MMT team experienced firsthand.