Machine Monitoring Software Automatically Collects Data for Easy Use

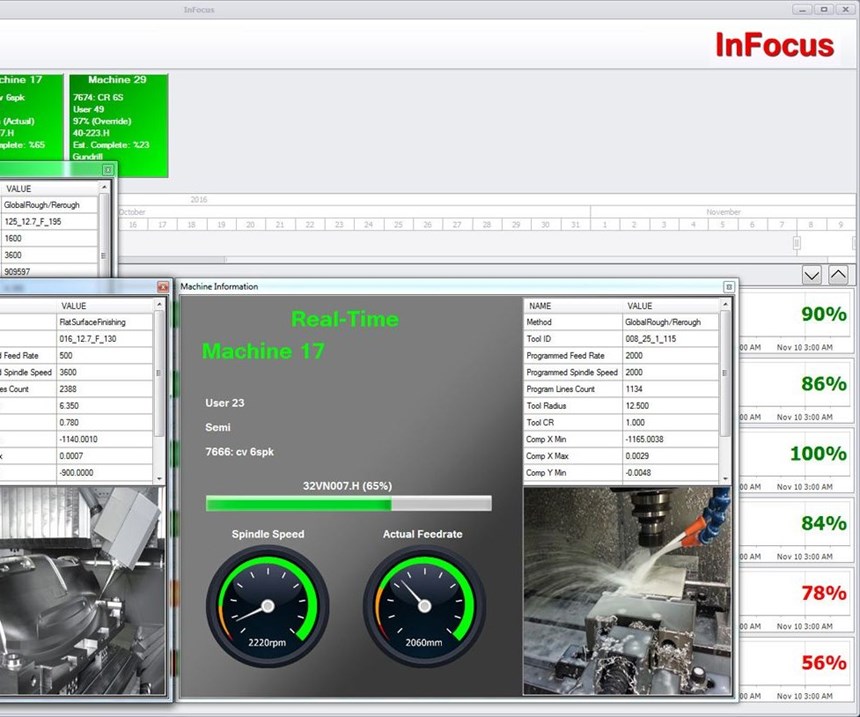

InFocus Machining is a complete machine monitoring and job tracking and analysis solution that automatically collects the machining hours of a job and each component.

RER Software features its InFocus Machining and InFocus Scheduling software at Amerimold 2018. InFocus Machining is a complete machine monitoring and job tracking and analysis solution that automatically collects the machining hours of a job and each component. Specifically designed for the mold and die tooling industry, InFocus Machining displays metrics and information relevant to an organization’s needs. The company says that the intuitive and easy-to-use technology ensures that adoption into an organization is seamless.

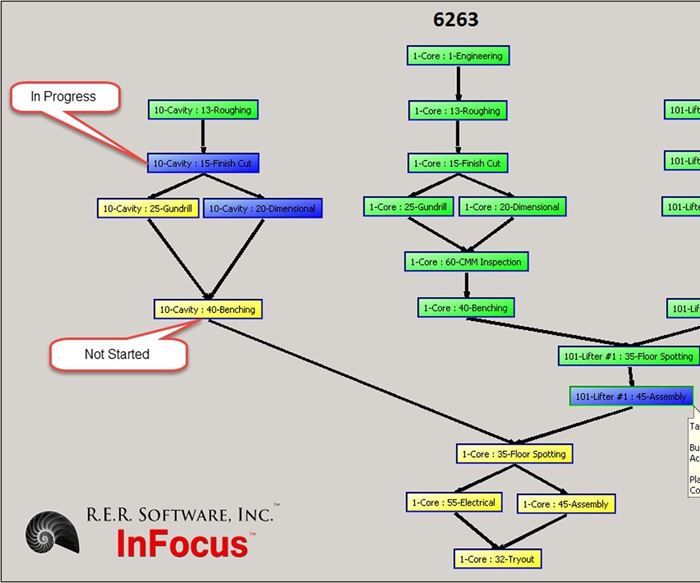

InFocus Scheduling is designed and developed specifically for the mold and die tooling industry to meet the challenges of day-to-day operations. The company says that InFocus Scheduling is easy to use yet centralizes the schedule for the organization, coordinates the work flow with line ups on the floor and highlights all potential scheduling issues with clear visibility into any open capacity on all resources.

Related Content

-

What Is Scientific Maintenance? Part 1

Part one of this three-part series explains how to create a scientific maintenance plan based on a toolroom’s current data collection and usage.

-

Indiana Mold Builder Decatur Mold Offers a History of Grit and a Future of Innovation

Decatur Mold Tool and Engineering Inc. serves as a tooling tour guide, helping busy tooling managers reduce uncertainty, lighten workload.

-

How to Manage a CAD Library

Learn five ways to organize your mold design information.