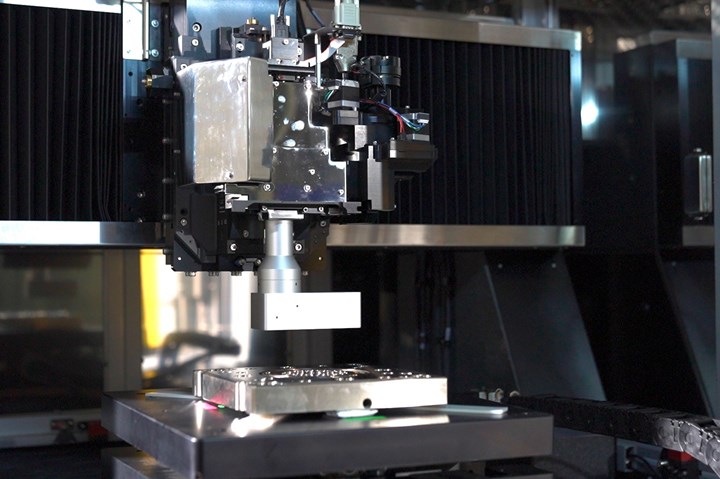

Large-Format Inspection Metrology System Maximizes Large Sample Flexibility

The Zygo Nexview 650 system enables 2D and 3D automated measurement of large, heavy parts, including injection molding tooling, PCBs, glass panels and more.

Photo Credit: Zygo

Zygo Corp. announces the launch of the Nexview 650, a large-format metrology system designed as an inspection tool for the automated measurement of injection molding tooling, PCBs, glass panels and other samples requiring an extended work volume up to 650 x 650 mm. The system provides 2D and 3D measurements of a variety of surface features with sub-nanometer vertical precision and sub-micron lateral precision.

The Nexview 650 is the latest addition to the Nexview range of 3D optical profilers from Zygo, which are all characterized by the ability to provide precise, quantitative, ISO-compliant, noncontact surface measurement. The production-oriented tool combines Zygo’s Nexview NX2 3D microscope head with a robust production platform, delivering micro- and nano-scale surface features, and captures millions of data points in seconds.

At the heart of the Nexview 650 is Zygo’s coherence scanning interferometry (CSI), a technology that uses specialized optical microscope objectives that not only provide the imaging and magnification of a surface, but also measure its 3D topography. CSI profiling is completely noncontact, which eliminates any chance of the sample being damaged. Also, in contrast with other microscope-based 3D topography techniques, Zygo says CSI has one distinct advantage: The height resolution of the measurement is consistent across all magnifications, whether the field of view is 20 μm, 20 mm or much larger. CSI offers high-precision, high-value surface metrology benefits, including measurements of all types of surfaces, sub-nanometer measurements, gage capable performance and SureScan vibration tolerance technology.

The systems’ large work volume accommodates both large and heavy parts. With an integrated operator station and a split axis motion design, its footprint is minimized. Integrated passive isolation is included to enable installation close to the manufacturing process to shorten the time to data.

Further, says Zygo, the Nexview 650 has been designed and built to ensure that it provides a return on investment for years to come. With a metrology area that accommodates lateral dimensions up to 650 x 650 mm, a sample load of >100 kg, a vertical range of 150 mm and options for a fully enclosed or partially enclosed system, the Nexview 650 reportedly provides maximum flexibility for large samples that require precision 3D optical profiling. The system can accommodate any standard PCB substrate panel sizes, custom-defined sample holders for flexible sheets and large, high-mass injection molding plates that benefit from precise, noncontact inspection to minimize potential surface damage.

Customized chucks and sample holders can be designed or supplied by customers to adapt the Nexview for smaller panels or singulated substrates, maximizing application flexibility. In addition, the Nexview 650’s integrated recipe-driven automation software enables hands-free metrology of multiple features on each panel, all in a single workstation, reducing production time and increasing process knowledge.

Related Content

-

What is Scientific Maintenance? Part 2

Part two of this three-part series explains specific data that toolrooms must collect, analyze and use to truly advance to a scientific maintenance culture where you can measure real data and drive decisions.

-

How to Achieve the Best Mold Finish

A look at factors that impact the polishability of tool steels and recommendations for obtaining a high-gloss finish.

-

Hands-on Workshop Teaches Mold Maintenance Process

Intensive workshop teaches the process of mold maintenance to help put an end to the firefighting culture of many toolrooms.