Internally Heated Sprue Bushings Optimize Melt Flow Control

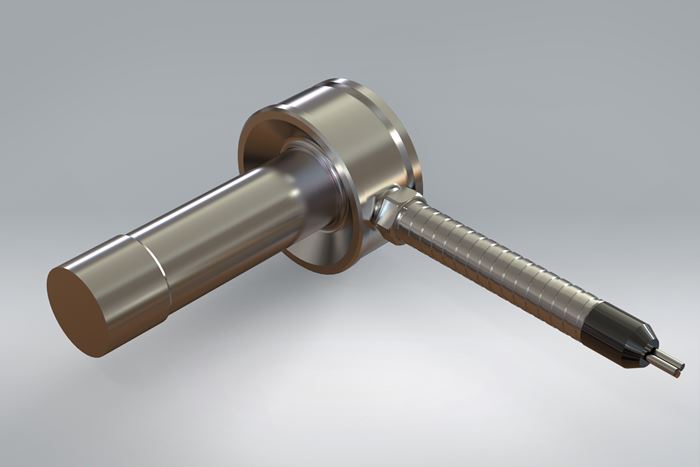

Melt Design Inc.’s Equatemp Single Zone Hot Sprue Bushings are internally heated and feature a high purity ceramic insulator, replaceable thermocouple and predetermined wattage distribution.

Equatemp Single Zone Hot Sprue Bushings from Melt Design Inc., a designer and manufacturer of hot runner systems and components, are the company’s latest offering of internally heated sprue bushings for injection molding.

Available in two styles, the solid body and the solid body with replaceable tips, the bushings are internally heated and feature a high purity ceramic insulator, replaceable thermocouple and predetermined wattage distribution, which the company says ensure the highest heat transfer rate, more accurate temperature readings and longer heater life.

With the Equatemp Single Zone or Dual Zone-style bushings, molders reportedly can gain better melt flow control for optimized quality parts shot after shot. In addition, Melt Design says the convenience of not having to do additional machining when retrofitting cold runner systems is said to save time and reduce costs.

Melt Design’s solid body (MB-style) bushing is available with extra stock when machining is required on the tip; the solid body with replaceable tips (RB-style) is offered with a choice of tip options: topless, full body and sprue-type to suit processing requirements.

Since 1984, Melt Design lnc. has specialized in the design and manufacture of failure-resistant, internally heated hot runner systems and components, servicing molders and moldmakers.

Related Content

-

How to Eliminate Chatter

Here are techniques commonly used to combat chatter and guidelines to establish a foundation for optimizing the moldmaking process.

-

Hands-on Workshop Teaches Mold Maintenance Process

Intensive workshop teaches the process of mold maintenance to help put an end to the firefighting culture of many toolrooms.

-

The Ins and Outs of Hot Runner Temperature Control

A training checklist that explains the why and how of proper hot runner temperature control and system management.