Integrated Molding Solutions Provider Features Mold Demos, IML Systems

NPE2024: Global moldmaker StackTeck Systems demonstrates a new approach to producing an ultra-thin, clear container made with 100% PET resin, mold and automation system innovations and more.

StackTeck Systems Ltd. is a global provider of integrated plastic molding solutions for the injection molding industry. From product and mold design to complete automation systems and systems integration, StackTeck develops injection molds and systems that provide effective and efficient production solutions.

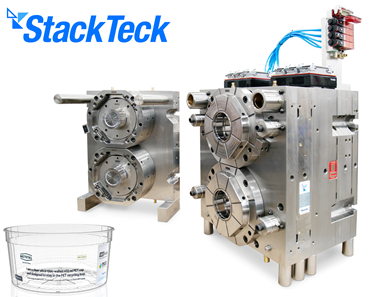

In its commitment to innovation and sustainability in food packaging alternatives, the company is demonstrating a new approach to producing an ultra-thin, clear container made of 100% PET resin. This container has a filling volume of 450 mL and is 100% recyclable. A two-cavity demo mold features StackTeck’s proprietary Thin Recess Injection Molding (TRIM) technology, which reduces the thickness of the container. This technology is combined with the company’s multi-gating approach to minimize the weight of the PET container.

The StackTeck in-mold labeling (IML) mold and automation system is also running at the Netstal booth (W223).

Related Content

-

Making the Circular Economy a Reality

Driven by brand owner demands and new worldwide legislation, the entire supply chain is working toward the shift to circularity, with some evidence the circular economy has already begun.

-

Dynamic Tool Corp. Wins MoldMaking Technology’s 2024 Leadtime Leader Award

Dynamic Tool Corp., a provider of engineered tooling solutions based in Menomonee, Wisconsin, has been awarded MoldMaking Technology’s prestigious 2024 Leadtime Leader Award. The announcement was made during a live awards ceremony at the Plastics Technology booth, where owners Steve and Ken Eberle accepted the award on behalf of their team.

-

Localized Mold Temperature Control Reduces Knit Lines, Optimizes Melt Flow

NPE2024: Dynamic localized mold temperature control Heat-Inject Technology by Incoe Corp. demonstrates how the part surface quality and the filling of the cavity is optimized with relatively little effort using targeted heat pulses.