Integrated Laser Automation Solution Controls Entire Production Process

Mitsubishi Electric Corporation offers its laser automation solution, a multifunctional, fully integrated system that is capable of controlling the entire production process from loading, cutting, sorting, and unloading through to the storage of finished parts.

Mitsubishi Electric Corporation, an established MC Machinery automation solutions partner, has teamed up with ASTES4 to offer its laser automation solution. This multifunctional system is the first fully integrated system capable of controlling the entire production process from loading, cutting, sorting, and unloading through to the storage of finished parts.

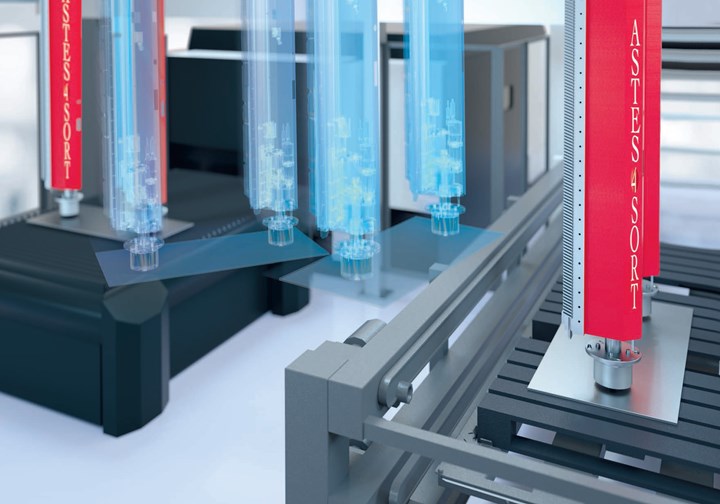

The system utilizes four cartesian grippers for loading, unloading, and the sorting of parts. Each gripper is capable of using vacuum or magnetic tools in a variety of shapes and sizes to produce a more effective sorting speed. The process sorts the parts into kits, and its wide variety of options allows for different material thicknesses to be kitted on the same pallet. Downstream processes are taken into account to provide seamless integration into the production process.

The system’s software automatically optimizes and manages the production process through to storage, without the user having to intervene. Remote access and a camera system enable continuous monitoring and intervention if needed.

Related Content

-

How to Automate Process and Design

Moldmakers can improve their operations and stop wasting time by taking these six steps for process and design automation.

-

CAM Automation Increases Mold Production, Quality

Mold builder switches CAM software package after 20 years to take advantage of innovative programming strategies that reduce mold machining programming and processing times.

-

Five-Axis Graphite Mill With Automation Debottlenecks Electrode Machining

Five-axis electrode cutting enabled Preferred Tool to EDM complex internal screw geometry on an insert that otherwise would have had to be outsourced.