Injection Mold Quotation Software Performs Quick, Accurate Quotations

Cadflow introduces QuickQuote, a software that enables users to perform quick and accurate budgets for the manufacture of molds.

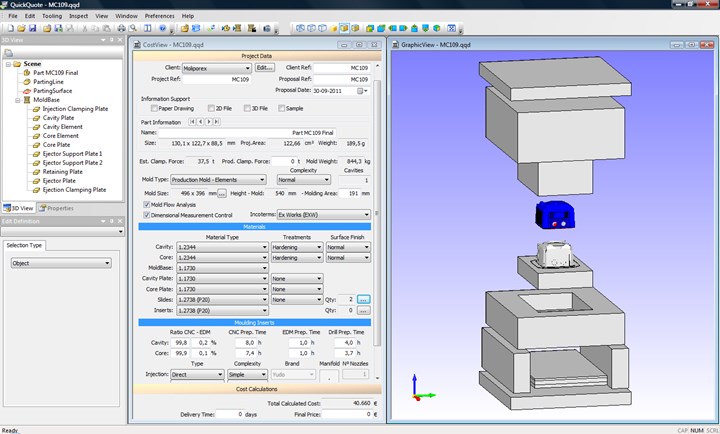

QuickQuote user interface with exploded mold base in 3D. Photo Credit: Cadflow

Cadflow introduces QuickQuote, a CAD-independent software solution to create quick, accurate and complete plastic injection mold quotations by calculating times and costs based on the 3D model of the plastic part(s). Overall, QuickQuote reportedly limits quotation errors and provides complete information to support the quotes.

QuickQuote offers several features, including categorization and specification of costs; automatic detection of negative zones and help in defining moving elements; automatic creation of commercial documentation; easy and quick definition of molding zones and movable elements; dynamic adjustment of the dimensions of plates and components; and automatic detection of ribs and other private details.

After choosing the 3D model of the part, Cadflow says the software calculates a value based on the characteristics of the part (such as the parting line and parting surface, slides, negative areas, etc.) and the preferences defined by the user. Any parameter change causes an immediate update of the final value, allowing users to quickly analyze different approaches in mold design. Further, the software is said to automatically produce preliminary mold drawings of the mold structure and representation diagrams of slides and lifters to ensure a better understanding of the work to be carried out.

QuickQuote allows the import of part geometry in STL format and all database parameters are fully customizable. It also comes pre-installed with average costs of materials and average costs per hour of work.

Related Content

-

How to Analyze and Optimize Cutting Conditions to Reduce Cycle Time

Plastic injection mold design and manufacturing company puts NC program optimization software module to the test. The results were surprising.

-

Tolerancing in Mold Design, Part 2: Using GD&T to Address Conventional Tolerancing Issues

Mold designers can achieve a single interpretation of workpiece functionality when following the American Society of Mechanical Engineers Geometric Dimensioning and Tolerancing standard.

-

How a Small Programming Change Cuts Cycle Time in Half

Overriding the CAM system when milling a series of lifter pockets helps to improve metal removal rate and increase feed rates.