Industry 4.0 Interface Facilitates Seamless Digital Connectivity for Manufacturers

GF Machining Solutions’ OPC UA interface reduces machine downtime, monitors performance across facilities, fully automates operations and ensure manufacturing process compliance.

With a focus on Industry 4.0, GF Machining Solutions now offers North American manufacturers the Open Platform Communications (OPC) Unified Architecture (UA) interface Version 1.0 as a single connectivity solution. The standard, developed by the OPC Foundation as a robust, cross-platform interface, provides a common communication language across GF Machining Solutions products, technologies and services, enabling easy connection to existing enterprise resource planning (ERP) systems and a wide range of other manufacturing solutions. GF says this offers users seamless data exchange for the collection and assembling of personalized key performance indicator (KPI) measurements at every level of operation, simplifying efforts to optimize processes.

Working in tandem with the OPC UA interface, GF’s other digital solutions, including the company’s rConnect Dashboard, are said to be able to help manufacturers reduce machine downtime, monitor performance across facilities, fully automate operations and ensure manufacturing process compliance. Version 1.0 of the OPC UA collects a wide range of comparable data and, with the rConnect Dashboard, makes that data accessible on the shop floor and/or remotely and via mobile devices.

GF Machining Solutions leverages OPC UA for gathering information from five data groups: machine identity, state/status information, process information, utilization and logs.

- Machine identity includes meta information, such as serial numbers, user-provided nicknames and software versions for GF Machining Solutions machines, all of which can be retrieved from the OPC UA server.

- The machine state data group lists basic information, such as the machine’s current assigned job, its activity status and more. With this data, manufacturers can then implement their own algorithms for tracking specific KPIs or overall equipment efficiency (OEE).

- For updates on process information, the OPC UA server provides remote access to messages from a machine itself. These include user messages, warnings and errors, enabling effective remote communications.

- With the OPC UA server, users can trace different KPIs since machine installation, including actual production time (APT), actual unit setup time (AUST), actual unit delay time (ADET), actual unit busy time (AUBT) and actual unit processing time (AUPT). In addition to these KPIs, the UnitTime and the UnitOnTime are trackable.

- For logging machine and job activity, users can access the OPC UA server to track the start and end times of jobs as well as multiple executions of a same job. The server also lists other key information about the last job the machine ran, such as lead time, start/end time and the numerical control (NC) program name used.

Because the interface involves connectivity to office networks and the internet, OPC UA features built-in security based on recognized standards such as Secure Sockets Layer (SSL), Transport Layer Security (TLS) and Encrypted Communication Data based on Advanced Encryption Standards (AES). This makes for a secure, robust and reliable communication infrastructure.

First released as OPC in 1996, the current OPC UA builds on what is now known as “OPC Classic” to enable true plug-and-play connectivity and platform-independent interoperability. Overseen by the OPC Foundation, GF says the current generation of OPC technology delivers a complete range of connectivity solutions with exceptional security and reliability. OPC UA is recognized as the IEC 62541 standard by the International Electrotechnical Commission (IEC).

Related Content

Achieving Flexible Capacity with Automation

This high-mix, low-volume manufacturer embarked on a year and a half program to introduce robotics to its manufacturing process.

Read MoreMold Builder Meets Increased Domestic Demand With Automated Cells

Burteck LLC experienced significant demand increases due to reshoring and invested in automated machining cells to step up its production output quickly and avoid losing business.

Read MoreAdvancing Moldmaking and Plastics: Trends in 3D Printing, Automation and Sustainability

NPE 2024 showcased the latest trends and technologies in innovation, efficiency and sustainability for moldmakers and molders, featuring advancements in 3D printing, automation, design and virtual reality/augmented reality/artificial intelligence.

Read More2024 Moldmaking Insights: A Year in Review Part 1

A look back at the top moldmaking trends of 2024, as revealed through MMT's analytics. This review highlights the most popular technical articles, case studies, tips and best practices that captured the industry's attention over the past year.

Read MoreRead Next

Predictive Manufacturing Moves Mold Builder into Advanced Medical Component Manufacturing

From a hot rod hobby, medical molds and shop performance to technology extremes, key relationships and a growth strategy, it’s obvious details matter at Eden Tool.

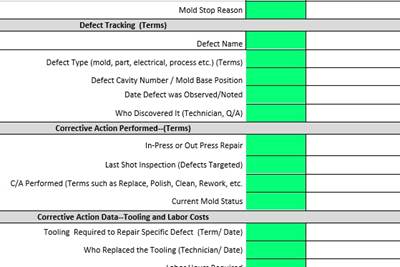

Read MoreWhat Is Scientific Maintenance? Part 1

Part one of this three-part series explains how to create a scientific maintenance plan based on a toolroom’s current data collection and usage.

Read MoreDo You Know Your Toolroom's Mold Maintenance Documentation Score?

Does your toolroom have a Reactive, Basic, Average, Best Practice or World Class culture when it comes to collecting and using Industry 4.0-type mold maintenance documentation? Steve Johnson and Glenn Keith of MoldTrax will help you answer that question during this FREE webinar on March 30 at 2PM EST.

Read More