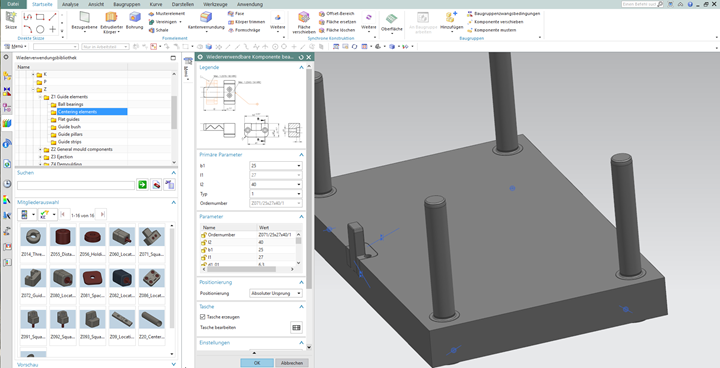

Fully Parametrized Native CAD Databases Reduce Design Time, Maximize Process Reliability

Native CAD databases from Hasco include installation spaces for an optimized design process and simplified implementation into CATIA, Siemens NX and SolidWorks CAD systems.

Share

Photo Credit: Hasco America

According to Hasco, its native CAD databases are well matched to the needs of modern moldmaking. The native data, generated in the original CAD systems—which include installation spaces—reportedly provides users considerable time and cost savings in the design process. Further, CATIA, Siemens NX and SolidWorks databases have now been extended.

In addition to including installation spaces in the individual design, together with the contour that needs to be removed, Hasco says the fully parametrized data also has decisive advantages if changes are required. This is because the relevant parts will automatically adapt to the corrections made. The parts list generated immediately afterwards guarantees a high level of process reliability and categorically rules out any incorrect orders, the company reports. The extensively automated ordering process ensures prompt delivery.

Additionally, links to the native databases are said to be easy to implement in the CATIA, Siemens NX and SolidWorks CAD systems. Hasco’s CAD/IT specialists also offer customers digital support through remote maintenance software and provide them with helpful tips on using the high-quality data.

Related Content

-

Tips for Tackling Mold Design, Machining, Cutting Tool and Wear Challenges

Tips for tasks ranging from reducing risk in part design and taking advantage of five-axis machining to refining cutting tool performance and reducing wear with guiding and centering systems.

-

What Is Scientific Maintenance? Part 1

How to create a scientific maintenance plan based on a toolroom’s current data collection and usage.

-

How to Manage Wall Thickness Changes in Your Mold Design

To ensure even filling and cooling, consider wall section transitions, corners and fillets, ribs and bosses, lip and rim designs and CAE flow simulation software.