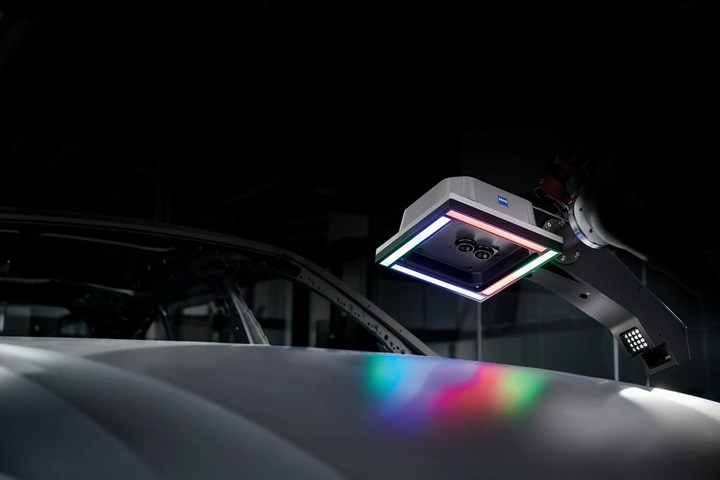

Fully Automated Inspection Sensor for Mold Surface Quality Assurance

Zeiss Abis III combines high-speed inspection with reliable detection of all relevant kinds of defects, ensuring a balance between inspection, speed, robustness, reliability and usability.

Share

Zeiss Industrial Quality Solutions present a new generation of the fully automated Abis surface inspection system. The new sensor, Zeiss Abis III, enables reliable and early inspection of the entire component surface, objectively evaluating and classifying all kinds of defects on a variety of metal surfaces including tool steels.

Abis III, a combination of projector, cameras, patented lighting and the new Zeiss Abis V20 software, is capable of detecting dents, bulges, sink marks, ripples, neckings, cracks and now also scratches, pressure marks as well as welding and gluing residue. With high precision, it can inspect moving and stationary parts inline or at line within cycle time, providing all fundamental data needed for targeted rework, quick surface analyses and process optimizations. According to the company, using Abis III means there is no need for conventional methods like manual visual inspections or surface treatment via grindstones.

The surface inspection system is equipped with a patented MCL Module. The Multi-Color-Light technology detects even the smallest types of defects at a detection rate of up to 20 Hz, requiring less than 0.5 seconds per sensor scan evaluation. Abis V20 software processes and visualizes potential component defects in pressed parts or in complete body-in-whites in real time. It evaluates surface defects in compliance with individual corporate standards and digitally saves the inspection results in a database. Thus, the quality certificate can be made available and provided to the customer whenever necessary. Moreover, when using Abis III, quality control loops across trades are said to be closed between the press shop and the body shop.

Related Content

-

Hands-on Workshop Teaches Mold Maintenance Process

Intensive workshop teaches the process of mold maintenance to help put an end to the firefighting culture of many toolrooms.

-

How to Achieve the Best Mold Finish

A look at factors that impact the polishability of tool steels and recommendations for obtaining a high-gloss finish.

-

Four Micro Tooling Considerations

Issues involving gating, ejection, mold splits and direction of pull are of special concern when it comes to micro tooling.