Free CAD Tool Streamlines Design and Part Ordering

Meusburger is releasing its Meusburger NX CAD tool for Siemens NX CAD systems free of charge. The tool automatically adjusts mold parts based on user input and includes quick access to Meusburger-specific data.

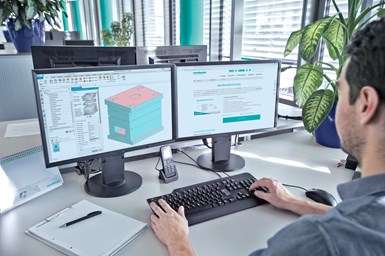

Together with its customer Schmidt WFT, Meusburger (Charlotte, N.C.) has developed a free CAD tool and library for the Siemens NX CAD system, enabling designers using the system to save time with the tool’s simple processes. Designers can selected configurations of components native to the system and automatically adjust all parameters. Installation spaces and the color table standards Meusburger developed together with the Association of German Tool and Mold Makers are also integrated in the tool.

Designers can use the Meusburger NX tool to work directly in the CAD system without using the shop, and to design components as native 3D data sets. Changes automatically populate, significantly reducing the time required for adjustments. Almost the entire mold-making range is in the tool. The system also includes all installation spaces with the respective tolerance and surface information. Integration of the Meusburger color table standards facilitates production without drawings.

Simple and efficient design

The Meusburger NX tool automatically regenerates the parts list and article codes after making changes, a massive efficiency improvement traditional list and code generation. The tool already contains all relevant data for design and manufacturing attributes such as tolerances, surface roughness and material, and allows for adjustments directly in the system. For example, when selecting installation parts in a different size, the installation spaces automatically adjust. Users can import the parts list into the shop via the Excel import function for ordering.

Tried and trusted design solution

This tool is available as a free download from the Meusburger website. Despite its low price, however, the company says it offers the advantages of several years of experience, know-how and continuous optimization according to customer requirements.

Related Content

-

Machine Hammer Peening Automates Mold Polishing

A polishing automation solution eliminates hand work, accelerates milling operations and controls surface geometries.

-

Solving Mold Alignment Problems with the Right Alignment Lock

Correct alignment lock selection can reduce maintenance costs and molding downtime, as well as increase part quality over the mold’s entire life.

-

How to Eliminate Chatter

Here are techniques commonly used to combat chatter and guidelines to establish a foundation for optimizing the moldmaking process.