Flat Line Hot Runner Nozzles Save Space for Installation

Heitec Hot Runner Systems’ Flat Line Nozzles reduce the mold base size. According to the company, this configuration represents an ideal gate location.

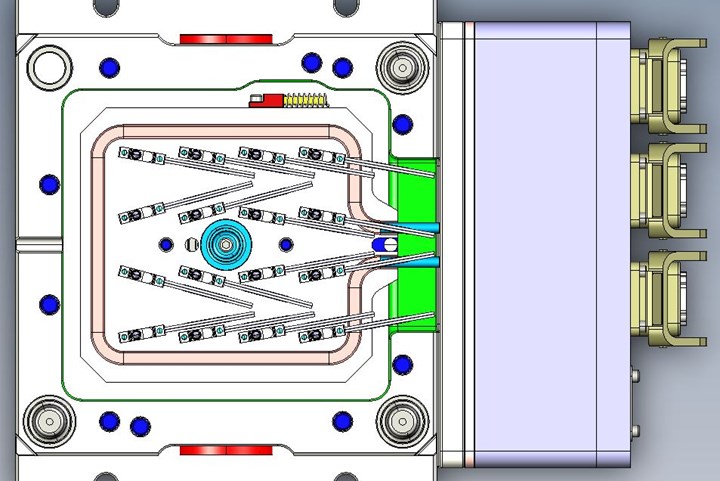

Heitec Hot Runner Systems, a manufacturer of hot runner systems based in Burgwald, Germany (available in North America through Technoject Machinery), has recently provided a space-saving solution using its Flat Line Nozzles. The goal for the system was to place a direct gate on an article that has limited gate well space available and to reduce the mold base size for this 16-cavity mold.

The direct gate was made possible by the narrow profile of the Flat Nozzle 01.041.06 reaching past the protruding article detail on the cavity side. This configuration reportedly represented the ideal gate location for the article. The article, which is used in the dispensing industry, weighs about 0.5 grams. The article is molded from a 35% glass-filled polybutylene terephthalate (PBT), which the company says requires the nozzle to have an excellent thermal profile and good wear-resistant properties. In addition, the small article weight demands a low residence time to avoid degradation. The small, 2.5 mm diameter nozzle flow channels reportedly ensure an optimum residence time in the system.

The angled nozzles of the system enable a more compact layout, which is said to result in an advantageous, smaller mold base size of 246 mm × 246 mm (9.685" × 9.685").

Related Content

-

Hands-on Workshop Teaches Mold Maintenance Process

Intensive workshop teaches the process of mold maintenance to help put an end to the firefighting culture of many toolrooms.

-

Fundamentals of Designing the Optimal Cooling System

The right mold components can help improve mold cooling and thereby produce higher-quality parts.

-

Revisiting Some Hot Runner Fundamentals

What exactly does a hot runner do? If you’ve been in the injection molding industry for any length of time, you might think the answer is obvious, but it is not.