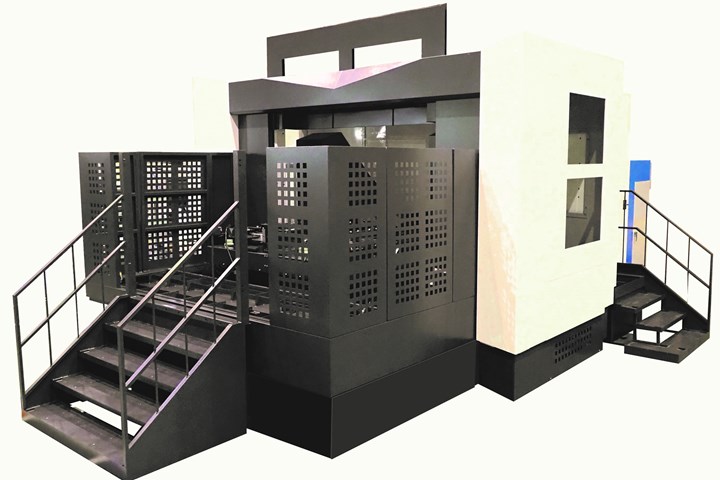

Five-Axis Horizontal Machining Center Executes Highly Rigid, Accurate Performance

Niigata Machine Techno expands its HX-5X boxway horizontal machining center series to include an ultra-large capacity HN80E-5X.

Photo Credit: Niigata Machine Techno USA

New to Niigata Machine Techno USA’s heavy-duty HN-5X series, the HN80E-5X 5-axis horizontal machining center features 49.2, 48.4 and 47.2 in. of travel in the X, Y and Z-axes respectively, and allows a maximum workpiece diameter of 49.2 in., a height of 39.4 in. and weight of 3,300 lb. Incorporating the solid cast iron X and Z base of Niigata’s HN100D-II Heavy Duty Boxway horizontal machining center, the HN80E-5X provides maximum rigidity, stability and accuracy. The product is ideal for machining in a range of industries demanding highly rigid, heavy-duty and accurate performance, including aircraft, automotive and die and mold.

Simultaneous 5-axis machining is said to improve cycle times and machined surfaces of complicated and 3D-curved components, with a reduced number of setups and simplified fixtures. Equipped with a 5-axis compensation function, high accuracy is ensured over extended time periods. Further, the tool magazine is driven by a servo motor for fast and reliable indexing.

The guide ways of the HN80E-5X consist of a combination of hardened and ground hand-scraped Turcite for stability, vibration damping and longer life. According to Niigata, the cross section of the rectangular guide ways is thick and wide for maximum machine rigidity; the machining center’s bifurcated bell-shaped column further contributes to this efficiency.

Both ends of Niigata’s heavy-duty 5-axis trunnion table are supported by the High Load Type Roller BRG and a Double-Lead Worm Gear System for low-frequency machining. For consistent long-life dynamic machine accuracy, the HN80E-5X is further equipped with an optical scale feedback system (on X-, Y- and Z-axes) and an inductive scale feedback system (on A- and B-axes) as standard.

A high torque, heavy duty spindle complements the rigid machine frame. The spindle head stock consists of mono-cast (single-piece) castings for more powerful milling and greater accuracy than bolt-together type spindle heads.

The HN80E-5X comes equipped with the FANUC 30iM controller. A variety of 5-axis machining support software is available.

Related Content

-

3D Printing Enables Better Coolant Delivery in Milling Operations

Just like 3D printing enabled conformal cooling channels in molds, additive manufacturing is now being used to optimize coolant delivery in cutting tools.

-

Moldmakers Deserve a Total Production Solution

Stability, spindle speed and software are essential consideration for your moldmaking machine tool.

-

Precision Meets Innovation at IMTS 2024

After attending IMTS, it's clear that the integration of advanced technologies is ready to enhance precision, efficiency and automation in mold manufacturing processes. It’s a massive event, so here’s a glimpse of what the MMT team experienced firsthand.