Fast Wire EDM Targets 3D-Printed Mold Component Removal

EDM Network introduces the EDMMax 434W that enables customers to economically cut 3D-printed mold inserts from their build plates.

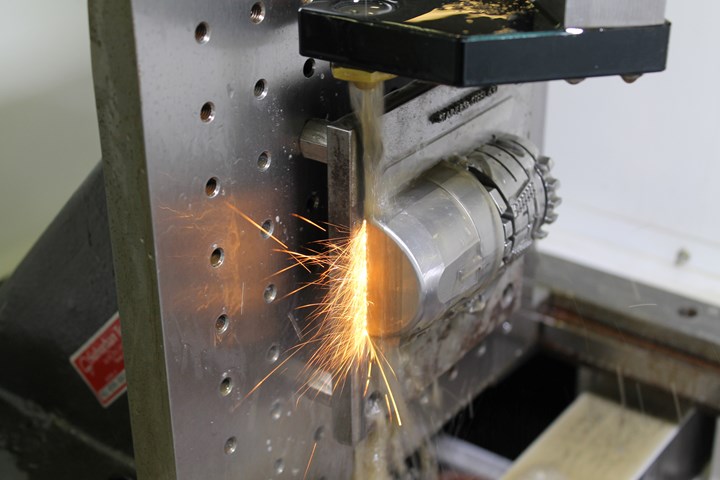

EDM Network Inc. is now offering an economical fast wire EDM solution with the EDMMax 434W for 3D-printed metal removal on parts like the mold inserts above, printed on the Matsuura Lumex Hybrid metal 3D printer/hard mill.

Among other applications, the EDMMax 434W enables companies like Matsuura to optimally cut 3D-printed mold inserts from their build plates. The fast wire EDM has a build plate size of 400 × 400 mm and includes four-axis cutting capability that enables it to cut 3D support structures or other shop-related parts; it uses a “reusable” 0.007'' diameter molybdenum high tensile wire.

Other EDMMax 434W features includes an on-board CAD system, or users can import programs via a USB port or LAN system. Three Pass Cutting technology is included for improved surface finishes and part accuracy.

This fast wire EDM solution is available in eight models including both vertical and horizontal cutting; most models include the four-axis on-board CAD system. All of EDM Network’s fast wire EDMs include on-site setup and training.

Related Content

-

Maintaining a Wire EDM Machine

To achieve the ultimate capability and level of productivity from your wire EDM on a consistent, repeatable and reliable basis, regular maintenance is a required task.

-

Hands-on Workshop Teaches Mold Maintenance Process

Intensive workshop teaches the process of mold maintenance to help put an end to the firefighting culture of many toolrooms.

-

Laser Welding Versus Micro Welding

The latest battle in finely detailed restoration/repair of mold materials.