Extended Mill Line Offers Speed and Precision for Moldmaking

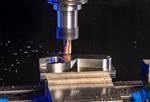

IMCO Carbide Tool Inc. highlights its M934 POW-R-FEED Mill, the latest extension of the company’s M93 POW-R-FEED line.

IMCO Carbide Tool Inc. highlights its M934 POW-R-FEED Mill, the latest extension of the company’s M93 POW-R-FEED line. This tool offers a good option for machinists aiming to save both time and money.

The M934 POW-R-FEED 4-flute end mills are engineered to cut materials machinists use most, including: All types of steel, titanium, plastics, brass, bronze and aluminum. The company says it is a good option for three- to five-axis machines, as the end mills ensure smooth, clog-free operation, even during complex movements, enabling faster feed rates, reduced cycle times, and greater profits.

The M934 POW-R-FEED excels at helical entry, ramping, slotting and standard peripheral milling. Aggressive flute and end-face geometries virtually eliminate clogging, while unique flute and core designs enable extremely aggressive tool paths, stepovers and depths. This tool is a good match when using aggressive cutting parameters.

The high-lubricity AlTiSN coating prevents chip buildup, enabling increased feeds and higher metal removal rates. Made from super-tuff carbide for superior strength, the M934 POW-R-FEED mill features fine cutting edges, edge prep for long life and a wiper flat end for smooth floor finishes.

For enhanced performance, M934 cutters are available with IMCO’s Chip Management System (CMS).

Related Content

-

6 Ways to Optimize High-Feed Milling

High-feed milling can significantly outweigh potential reliability challenges. Consider these six strategies in order to make high-feed milling successful for your business.

-

Hands-on Workshop Teaches Mold Maintenance Process

Intensive workshop teaches the process of mold maintenance to help put an end to the firefighting culture of many toolrooms.

-

It Starts With the Part: A Plastic Part Checklist Ensures Good Mold Design

All successful mold build projects start with examining the part to be molded to ensure it is moldable and will meet the customers' production objectives.

.png;maxWidth=970;quality=90)

.png;maxWidth=300;quality=90)