Excellence Center Enables Innovation Manufacture of Molds, Dies

The DMG MORI Die & Mold Excellence Center highlights its DMU 210 P machine maximized to produce highly demanding molds and dies with quality and precision.

With innovative manufacturing solutions and holistic processes, the DMG MORI Die & Mold Excellence Center enables its customers to economically produce sophisticated tools and molds.

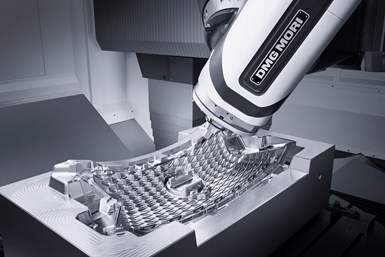

Plastic injection grill mold manufactured on a DMU 210 P. Photo Credit: DMG MORI USA Inc.

The plastic injection grill mold shown in the image below is produced on a DMG MORI DMU 210 P in a two-stage roughing and finishing process. Machining the 42CrMo4 steel component takes a total of 508 hours.

Thanks to the five-axis technology, 50% of the previous EDM process and 50% of the manual polishing work could be eliminated and an overall accuracy of +/- 394 µin to +/- 984 µin could be achieved.

With its symbiosis of high productivity and maximum precision, DMG MORI adds that the DMU 210 P is generally ideal for producing highly demanding molds and dies with quality and precision. In addition, the universal machine offers an optimum performance level with simple operation and at economic conditions.

Related Content

-

Mold Innovations Power Unique Auto Lighting Elements on Hummer EVs

Diamond machining, electroforming of micro-optical inserts and modified latch-lock system help injection molds produce unique forward lighting elements.

-

Moldmakers Deserve a Total Production Solution

Stability, spindle speed and software are essential consideration for your moldmaking machine tool.

-

Hybrid Milling/Drilling Machine Reduces Total Mold Machining Time

MSI Mold Builders now squares, plus drills and taps eye-bolt holes on 50% of its tools in a single setup using a five-axis milling/drilling center with a universal spindle.

.jpg;maxWidth=970;quality=90)