Cooling, Mold Temperature Control Solutions Augment Energy, Water Savings

NPE2024: Frigel North America is presenting improvements to many of its processing cooling equipment, as well as debuting new options for North American customers, such as the Microgel series, 3DP4 4.0, 4DK series and more.

Microgel RSY Syncro Series. Source (All Images) | Frigel North America

Frigel North America presents its latest process cooling solutions designed especially for the industrial processing of plastics in automotive, packaging, medical, chemical, pharmaceutical, household and more. The company’s technologies focus on maximizing productivity, energy and water savings.

New and optimized cooling and temperature control systems on display include:

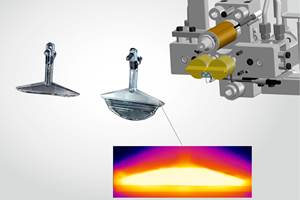

Microgel RSY Syncro

This year, Frigel is celebrating the 30-year anniversary of its Microgel product line with new Microgel innovations. The RSY Syncro, a machine-side unit that improves temperature control method for injection molding, reportedly provides a 50% increase in productivity, and up to 40% reduction in cycle times (thanks to reduced cooling time), while maintaining the surface quality, dimensional characteristics and mechanical performance of the finished products. Digital synchronization with the molding process ensures that it doesn’t require modifications to any of the mold design or molding parameters, making the system communicate with the press while remaining completely autonomous and easily implemented by operators.

The Microgel Syncro product line features more than 10 models, with cooling capacities from 4.5 to 16 tons and heating capacities from 12 to 24 kW. Compared to traditional methods, the Syncro control unit supplies cold water to the mold only during the cooling phase, reducing its duration.

Ecodry 4DK Series

Frigel expands its adiabatic product family line, introducing the Ecodry 4DK series, designed for flexible configuration of modular adiabatic solutions for small to large plastic factories. 4DK takes advantage of some of the technological advances already introduced in the LDK range (efficient PADs, new generation of EC fans, modular design, wide and deep configurations).

4DK is characterized by a high efficiency humidification system (Coolpad) and by a new generation of EC fans which, combined with a more effective dry cooler, obtain a new level of compactness in a powerful new adiabatic cooler product line.

The Ecodry 4DK is designed to integrate easily into existing Ecodry 3DK systems, of which Frigel has an existing installation base of thousands of units, in addition to responding to the new needs of industries — energy efficiency, sustainability and raw resource saving such as water.

Netgel 3PR 4.0

The 3PR 4.0 product platform is a Frigel solution that provides complete control of Frigel central cooling systems. 3PR 4.0 control meets the needs of processors to supervise and manage the entire cooling system from a single control point. All the connected central system components are controlled via a control panel that has been designed specifically for Frigel systems. 3PR 4.0 is available in two versions, Lite and Premium, depending on the size of the system and the equipment to control.

Full native connectivity to MiND and its new HMI offer a comprehensive user experience and compatibility with Industry 4.0 architectures, providing easy visualization and process diagrams of the connected equipment, dashboards for main parameters, performance graphs, and alarm management and history.

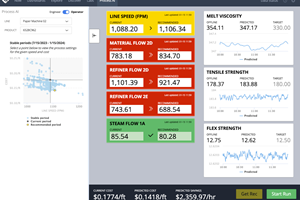

Negel MiND

Frigel releases the MiND 2.0 platform to North American customers, the evolution of its Industry 4.0 concept. MiND 2.0 is said to meet the ever-increasing needs of modern companies to reach Industry 4.0 and IIOT standards. It is now able to provide customers a supervision and maintenance tool for all Frigel equipment and accessories, both central and machine-side, enabling monitoring and management of all working parameters and events and registering performance and energy consumption of every single cooling system component through a multifunctional user interface, both locally and remotely, through a user-friendly webpage.

HB-Therm Thermo-6 Series

HB-Therm Thermo-6 Series.

Frigel North America, the exclusive sales, parts and service distributor in North America for HB-Therm TCUs, debuts the Thermo-6 product line. Equipped with standard VFD, seal-free, reversible, stainless steel pumps, all new, noncontact heater design with life-time warranties, 8-16-kW heating capacities and new cabinet design, these closed-circuit TCUs are built with Swiss technology and optimized mechanical and control features. They include standard features, such as ultrasonic flow meters, large 7" touchscreen HMIs, e-cockpit via Bluetooth and Wi-Fi, ethernet connections and several interface protocols.

Microgel RS Series

Frigel also releases the full range of its Microgel RS Series for injection molding to North America. These single- and dual-zone machine-side temperature control units are designed for molding throughputs ranging from 20-530 lbs/hr. The new Microgel RS range includes important advancements in temperature accuracy over the entire control range (23-194°F), functionalities, pumping performance and overall energy efficiency.

The RS range features additional configurations specifically designed for packaging and Extrusion. Options such as flowmeters, VFDs, return/remote temperature sensors enable full process control capability. Its new user interface offers an improved experience and full connectivity and interoperability via the Frigel MiND platform.

Related Content

Making the Circular Economy a Reality

Driven by brand owner demands and new worldwide legislation, the entire supply chain is working toward the shift to circularity, with some evidence the circular economy has already begun.

Read MoreNPE 2024 Set to Showcase Solutions for 6 Key Moldmaking Trends

The moldmaking and plastics industries have undergone some changes in the past six years, all of which emphasize the importance of innovation and adaptability for competitiveness.

Read MoreUse AI, Machine Learning to Take Variability Out of Manufacturing

Variability has always created insurmountable challenges for manufacturers. However, in the last decade, impact has been more painful due to a lack of experienced workforce. By leveraging technological advancements, particularly in AI, manufacturers can gain a transformative competitive advantage in both cost reduction and workforce development.

Read MoreLocalized Mold Temperature Control Reduces Knit Lines, Optimizes Melt Flow

NPE2024: Dynamic localized mold temperature control Heat-Inject Technology by Incoe Corp. demonstrates how the part surface quality and the filling of the cavity is optimized with relatively little effort using targeted heat pulses.

Read MoreRead Next

Temperature Control Unit Enables Cycle Time Cuts

The Microgel Syncro control unit from Frigel North America supplies cold water to the mold only in the cooling phase.

Read MoreSelf-Contained Portable Air-Cooled Chiller Displays High Energy Efficiency, Low Life

MRS industrial-grade chillers are now offered in Frigel North America’s product line, with chilling capacities of 3.5-15.5 tons and low maintenance.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read More