Comprehensive Deep-Hole Drilling Support Multiple Manufacturing Operations

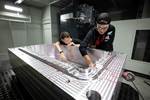

IMTS 2024: Unisig’s full range of deep-hole drilling applications, paired with its engineering, sales and service support, provide a breadth of technology coverage for mold and die, automotive and other industries.

Unisig is displaying its comprehensive portfolio of deep-hole drilling solutions. Manufacturers in industries ranging from aerospace, automotive, medical and moldmaking to energy, firearms and defense have the opportunity to learn more about these deep-hole drilling technology and automation options, paired with Unisig’s engineering, sales and service support.

The company offers an entire deep-hole drilling system — machines, tooling and automation — that covers the full range of deep-hole drilling applications. Engineered and manufactured in the U.S., Unisig machines are used in applications that can vary from drilling holes less than 0.040" in diameter for titanium medical components to 20"-diameter holes that are over 30' deep in large, high-strength forgings.

One solution example, the USC-M drilling and milling centers, combine five-axis CNC milling and deep-hole drilling in one machine platform for maximum versatility with fewer setups and reduced part handling — all features that are advantageous to moldmaking. In addition, Unisig’s solutions can handle heavy weight capacity for machining complete parts, not just side features, making them efficient for handling the demands of large molds.

Productivity and cost efficiency are maximized with Unisig’s experience in designing and integrating a variety of standard and specialized automation solutions into its deep-hole drilling machines that include pallet changers, robotics, programmable smart conveyors, heavy bar loaders and bulk feeders.

In addition, visitors are able able to view an assortment of parts from medical to aerospace components that demonstrate the breadth and depth of Unisig’s deep-hole drilling capabilities. Unisig personnel are also available to discuss machine tooling and automation solutions for those customers with distinctive manufacturing needs and challenges and detail the company’s dedication to comprehensive training and support.

Related Content

-

Moldmakers Deserve a Total Production Solution

Stability, spindle speed and software are essential consideration for your moldmaking machine tool.

-

How to Eliminate Chatter

Here are techniques commonly used to combat chatter and guidelines to establish a foundation for optimizing the moldmaking process.

-

How to Produce More Accurate Molds and Reduce Rework

Patented micro-milling process for manufacturing steel plate flat and parallel helps mold builders shorten mold build times and increase accuracy.