CNC Simulation Software Focuses on Smarter, More Informed Mold Manufacturing

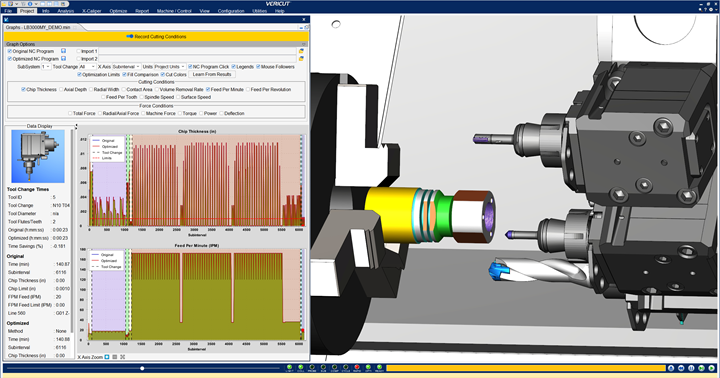

The latest version of CGTech’s CNC simulation software, to be demoed at IMTS 2022, incorporates enhancements and new features focusing on using data for smarter, more efficient manufacturing processes.

CGTech is attending IMTS 2022 at booth #133340 where it provides demonstrations of the latest version of its CNC simulation software, Vericut 9.3. This release focuses on creating “smarter,” more efficient manufacturing processes, CGTech says, by incorporating data from the machine, tools and stock material to improve the quality of the simulation and the manufacturing workflow. Version 9.3 is said to bring notable improvements for manufacturers in moldmaking, specifically within Force optimization.

Force, Vericut’s physics-based optimization module, reduces cycle times, improves tool life and prevents undue wear on CNC machines. According to the company, Force does this by optimizing feed rates and spindle speeds for each cut in an NC program to achieve a constant maximum chip thickness. The latest improvements to Force limit tool deflection, which enables users to achieve better machined part quality and improved surface finishes, as well as long tool and spindle bearing life. These deflection calculations have been expanded to account for the entire rotating tool assembly, including holders, indexable mills and CAD models used as tools.

Along with improved deflection calculations, Vericut 9.3 also includes a Tool Performance Database (TPD) within Tool Manager, which suggests starting spindle speed and feed rate values for cutters. CGTech says this data works hand in hand with Vericut’s Machining Optimization Data (MOD), which displays a table of spindle speeds and feed rates to help programmers achieve their desired cutting conditions. TPD and MOD values are based on the type of cutter being used, the material of the workpiece being machined and the chosen cutting operation method (roughing or finishing).

Related Content

-

What is Scientific Maintenance? Part 2

Part two of this three-part series explains specific data that toolrooms must collect, analyze and use to truly advance to a scientific maintenance culture where you can measure real data and drive decisions.

-

Tolerancing in Mold Design, Part 2: Using GD&T to Address Conventional Tolerancing Issues

Mold designers can achieve a single interpretation of workpiece functionality when following the American Society of Mechanical Engineers Geometric Dimensioning and Tolerancing standard.

-

How to Fix Predicted Warpage Before It Happens with Windage and CAD Model Morphing

Applying windage and model-morphing techniques saved toolmaker/molder Sturgis Molded Products the time, cost, headaches of multiple part/mold design iteration loops, cumbersome cooling fixtures, and long molding cycles.