CNC Machine Simulation, Verification, Optimization Software Machines More Accurate Moldmaking Components

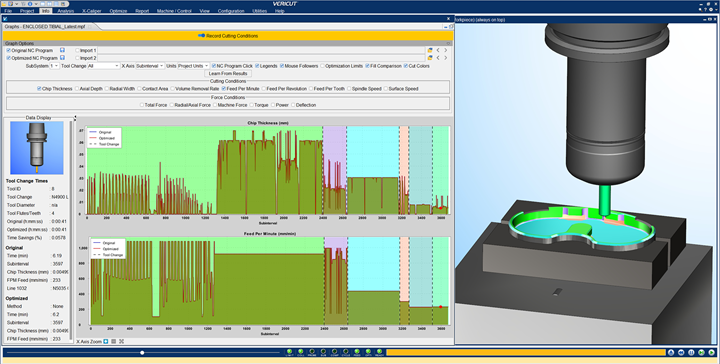

VERICUT 9.2 by CGTech offers new features and improvements to preserve machines and cutting tools, increase machine capacity and dramatically reduce repair and scrap costs.

Photo Credit: CGTech

The latest release of VERICUT, a CNC machine simulation, verification and optimization software by CGTech, offers new features and improvements to preserve machines and cutting tools, increase machine capacity and dramatically reduce repair and scrap costs. With improved accuracy to collision checking and overall performance, VERICUT’s machine simulation is said to make it easier to verify and optimize an NC program before running it on a machine.

VERICUT Force is a physics-based NC program optimization module that provides a proactive analysis of NC programs with a visual analysis of the program and the graphic review window to enable users to quickly and easily visualize what’s happening with each cut. Force analyzes and optimizes cutting conditions throughout the NC program operation according to the provided material, cutting tool and machining conditions. The program also displays a side-by-side comparison of data such as power and torque, chip thickness, material removal rates, tool deflections and feed rates for both the original NC program and the Force-optimized version to show changes from under-utilized cutting conditions.

Overall, CGTech contends that Force-optimized parts save time and money throughout the manufacturing workflow, preserving tool and machine life while producing parts with better finishes.

Related Content

-

What is Scientific Maintenance? Part 2

Part two of this three-part series explains specific data that toolrooms must collect, analyze and use to truly advance to a scientific maintenance culture where you can measure real data and drive decisions.

-

What Is Scientific Maintenance? Part 1

Part one of this three-part series explains how to create a scientific maintenance plan based on a toolroom’s current data collection and usage.

-

It Starts With the Part: A Plastic Part Checklist Ensures Good Mold Design

All successful mold build projects start with examining the part to be molded to ensure it is moldable and will meet the customers' production objectives.