CAD Software Improves User Functionality

Kubotek Kosmos software enhanced with updated CAD file readers, added support for mesh objects and improved large assembly visualization capabilities.

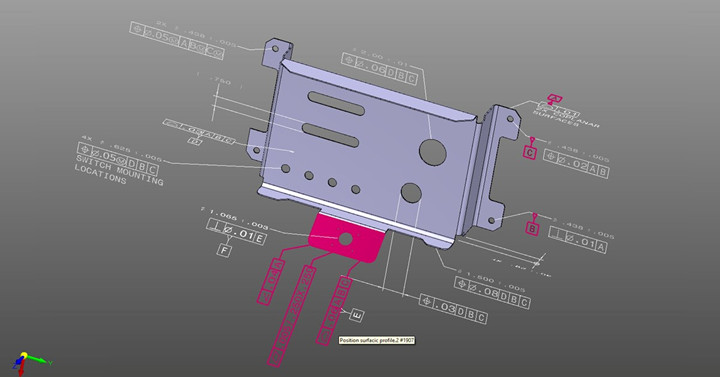

Photo Credit: Kubotek Kosmos

Supply chain software provider Kubotek Kosmos has announced the 4.0 release of the Kubotek K-Compare and K-Display software products. This release provides updates to CAD file readers, user interface improvements and several new functions for each product. The new releases are available for customers to download immediately.

For example, reading of 3D CAD files across all 4.0 Kubotek software programs has been updated to support new versions of ten CAD file formats:

- Autodesk Inventor 2022

- Dassault Systemes (DS) CATIA V5 R2021x (R31)

- DS V6/3DExperience R2021x

- DS SolidWorks 2022

- DS Spatial ACIS 2022

- PTC Creo 8.0

- Siemens Digital Industries Software (SDIS) NX 2000 (1980 Series)

- SDIS Solid Edge 2022

- SDIS Parasolid V34

- SDIS/ISO JT 10.7

Support for the Solid Edge sheet metal part format .psm has also been added to all K-Compare and K-Display products. Kubotek KeyCreator support in K-Compare products has been updated to the 2022 CKD file format.

Kubotek’s K-Compare Revision and Validate products are said to enable absolute clarity in engineering changes and movement of 3D data. Both products are able to quickly read the structure of large CAD assemblies from all major CAD applications, Kubotek3D says. With the 4.0 release, K-Compare products now provide users the option to open/view selected parts from within the list of parts in the assembly.

The 4.0 release of K-Compare Validate adds support for several types of 3D data requested by customers. The first added data type is Stereolithography (STL) mesh commonly used in 3D printing and additive manufacturing (AM). With the Premium level of the 4.0 release, STL files can now be compared back to the CAD file which they approximate. K-Compare Validate will alert users if the STL file deviates from the original within a user-defined precision and record that this check was completed for quality compliance requirements. The second data type with additional support is Product Manufacturing Information (PMI) such as tolerancing attached to faces in STEP AP242 models. K-Compare Validate 4.0 provides full semantic comparison of STEP AP242 PMI to confirm these annotations have transferred correctly from the originating CAD file. The last new data type supported for compare is 3D wireframe entities stored in the KeyCreator CKD format.

K-Display View and Convert are reported to be easy-to-use, multi-platform applications which enable anyone to open nearly any CAD file and republish models to standard formats. The 4.0 release adds the ability for users to review properties such as the volume and center of gravity of lightweight 3D objects saved as mesh entities. The file formats from which these meshes can be read include STL, CGR, 3DXML, STEP and KFW. This feature works the same way as reviewing properties of precise 3D objects saved as solid entities, Kubotek notes. In either case, this information can be valuable for estimating material quantity or weight for cost estimating or process planning.

A new ability to move and/or rotate objects relative to each other has been introduced. Moving objects apart from each other enables users to better visualize a complex assembly in which some part and sub-assembly locations in the original CAD assembly file obstruct the view of other parts. The ability to export files to a 3D PDF file has also been added to K-Display products in the 4.0 release.

Moreover, a new capability to discover assembly structure aids users in improving the understanding of a complex set of parts saved in a single file by automatically sorting identical sets of solid entities into a single reference entity linked to each location.

Free trials of Kubotek software are available.

Related Content

How to Manage Wall Thickness Changes in Your Mold Design

To ensure even filling and cooling, consider wall section transitions, corners and fillets, ribs and bosses, lip and rim designs and CAE flow simulation software.

Read MoreHow to Fix Predicted Warpage Before It Happens with Windage and CAD Model Morphing

Applying windage and model-morphing techniques saved toolmaker/molder Sturgis Molded Products the time, cost, headaches of multiple part/mold design iteration loops, cumbersome cooling fixtures, and long molding cycles.

Read MoreWhat is Scientific Maintenance? Part 2

Part two of this three-part series explains specific data that toolrooms must collect, analyze and use to truly advance to a scientific maintenance culture where you can measure real data and drive decisions.

Read MoreMold Design Review: The Complete Checklist

Gerardo (Jerry) Miranda III, former global tooling manager for Oakley sunglasses, reshares his complete mold design checklist, an essential part of the product time and cost-to-market process.

Read MoreRead Next

How to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read More