CAD-Embedded Motion Simulation Helps Moldmakers Slash Design Times

The latest version of the Dynmik Design for Mold add-on from Longterm Technology Services cuts design validation time by as much as 80% and is 10 times more power when validating complex or precise motions.

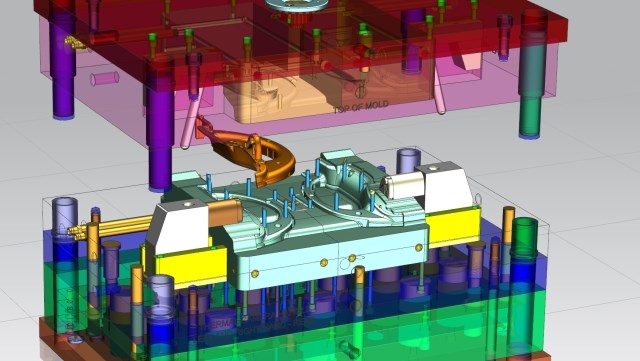

Dynmik Design for Mold. Photo Credit: Longterm Technology Services

Longterm Technology Services has released the latest version of its Dynmik Design for Mold add-on for Siemens NX CAD software. Powered by the Mach 3 Mold Design package, this software has reportedly helped mold designers across North America design more complex tools while cutting their design validation time by as much as 80%. The software can easily be used by CAD designers with less than a single day of training thanks to its streamlined, industry-specific interface. Further, Longterm Technology Services contends that the latest release has responded to significant demand from industry by offering users the ability to set minimum zones of clearance between components once the mold is put in motion. If the mold design violates any clearance requirements (including hard collisions), the system will alert the designer of the issue and suggest steps for remediation.

The latest release of Dynmik Design for Mold also provides users the ability to run motion simulation with 0.1 increments instead of the previous 1.0, giving designers 10 times more power when validating complex or precise motions. Designers can use the software to easily visualize motion curves around components and duplicate existing defined components with all motion parameters and define different geometries, the company notes. This helps divide components with a large number of geometries into smaller segments for receiving more manageable collision-checking results downstream.

Related Content

-

Tolerancing in Mold Design, Part 2: Using GD&T to Address Conventional Tolerancing Issues

Mold designers can achieve a single interpretation of workpiece functionality when following the American Society of Mechanical Engineers Geometric Dimensioning and Tolerancing standard.

-

It Starts With the Part: A Plastic Part Checklist Ensures Good Mold Design

All successful mold build projects start with examining the part to be molded to ensure it is moldable and will meet the customers' production objectives.

-

Tips for Tackling Mold Design, Machining, Cutting Tool and Wear Challenges

Tips for tasks ranging from reducing risk in part design and taking advantage of five-axis machining to refining cutting tool performance and reducing wear with guiding and centering systems.