Bonding, Sintering Tech Advances Metal Bonding for Mold, Die Components

NPE2024: Punch Industry USA exhibits P-Bas, intended to replace the use of 3D printers when producing mold and die components, as well as a variety of mold component supplies.

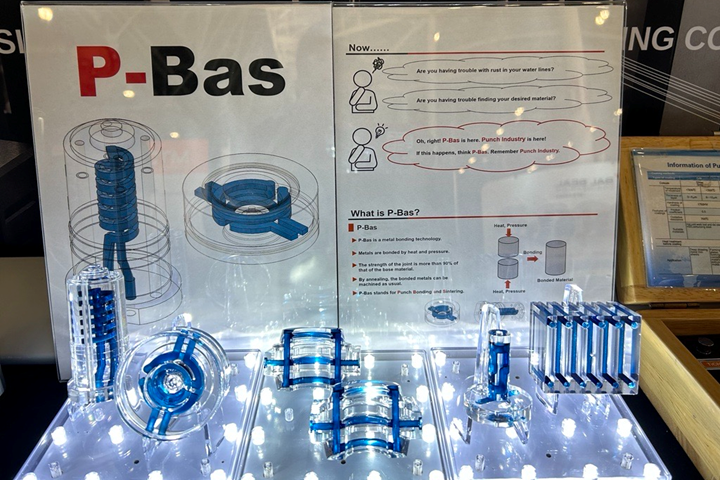

Punch Industry USA Inc., subsidiary of Tokyo-based Punch Industry Co., is exhibiting its parent company’s bonding and sintering technology called P-Bas. P-Bas, an alternative to 3D metal printing, is used to fabricate custom conformal cooling channels for mold and die components by bonding split parts, offering an extensive compatibility with iron-based materials. Punch Industry has applied for a patent for this novel technology.

P-Bas, denoting Punch Bonding and Sintering, employs heat and pressure for metal bonding, achieving joint strength surpassing 90% of the base material. Additionally, P-Bas produces parts and cooling lines with a finer, smoother surface finish than that of 3D metal printed parts; the process includes a surface coating to reduce rust formation in the cooling lines.

Parts that can be made using P-Bas include gate inserts for components to make plastic bottles, core pins for injection and die-cast molds, and sprues.

Customers can initiate the P-Bas ordering process by designing components with cooling channels, approving suggested split parts and receiving a quotation. Rigorous testing, encompassing bend tests for joint strength and leak tests for watertight integrity ensures the reliability of P-Bas technology.

Punch Industry USA is also exhibiting its precision-ground custom mold cores, core pins, ejector pins, ejector sleeves, ejector blades, micro pins, punches, button dies and more for the medical, beverage, electronics, automotive, factory automation and other industries.

Related Content

-

It Starts With the Part: A Plastic Part Checklist Ensures Good Mold Design

All successful mold build projects start with examining the part to be molded to ensure it is moldable and will meet the customers' production objectives.

-

Solving Mold Alignment Problems with the Right Alignment Lock

Correct alignment lock selection can reduce maintenance costs and molding downtime, as well as increase part quality over the mold’s entire life.

-

How to Eliminate Chatter

Here are techniques commonly used to combat chatter and guidelines to establish a foundation for optimizing the moldmaking process.