Advanced CNC Programming Interface Streamlines Tool Management

HCL announces the implementation of Zoller TMS Tool Management Solutions Interface in HCL CAMWorks software to decrease manual entry of tool data and eliminate the need for multiple databases.

Share

Read Next

Photo Credit: HCL Technologies

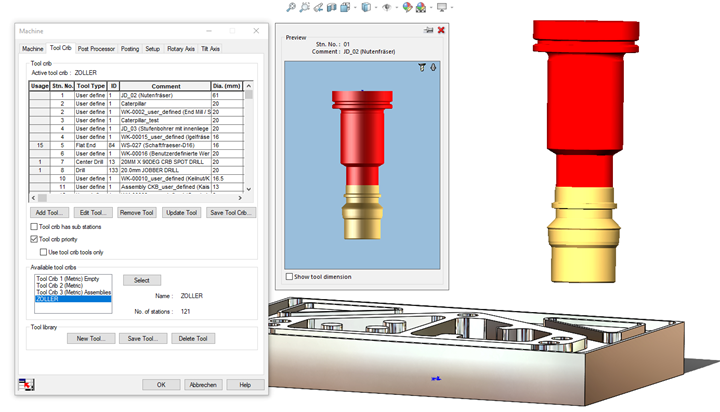

HCL Technologies (HCL), a global technology company, announces the implementation of Zoller TMS Tool Management Solutions Interface in HCL CAMWorks software. The Zoller Interface is said to supply customers with advanced tool database management options, an overview of available tools and eliminate the need to maintain multiple tool databases.

With the Zoller Interface in CAMWorks, tool data is standardized and the exchange of data between the two software systems is automated. Customers only need to enter the information for their cutting tools in once into the central Zoller tool database, HCL says, and the tools are imported automatically into CAMWorks. All of the tool parameters are captured, including contour line for holder and cutter, specific tool type and technology data, such as feeds and speeds. The interface also enables users to define tools in the Zoller TMS Tool Management Solutions software with the same tool types and parameters that are being used in CAMWorks.

Once a part model is programmed, the Zoller Interface generates a setup sheet that includes a list of tools used for the part. The setup sheet assists with tools assembly, measurement and sending measured values to the machine for cutting the parts. According to HCL, the interface decreases manual entry of tool data and streamlines tool management.

Related Content

-

Indiana Mold Builder Decatur Mold Offers a History of Grit and a Future of Innovation

Decatur Mold Tool and Engineering Inc. serves as a tooling tour guide, helping busy tooling managers reduce uncertainty, lighten workload.

-

How to Use Scientific Maintenance for More Accurate Mold and Part Troubleshooting

Discover how adopting scientific maintenance approaches helps improve mold lifespan, minimize failures, and optimize production outcomes.

-

MMT Chats: Solving Schedule and Capacity Challenges With ERP

For this MMT Chat, my guests hail from Omega Tool of Menomonee Falls, Wisconsin, who share their journey with using enterprise resource planning (ERP)—and their people—to solve their schedule and capacity load monitoring challenges.