Products

Rail Transport System on Thermoformer Reduces Waste

SencorpWhite says that the Ultra 2 thermoformer is 70 percent faster than previous models.

Read MoreMachine Vise Features Clamping Slider

Hirschmann Engineering offers a machine vise with a clamping slider and optional features for high-precision clamping.

Read MoreCollaboration Features Power of Machining, Molds and Robotics

The Boy Machines booth at NPE2018 features a machine from Boy Machines, molds from M.R. Mold & Engineering, a mold base and sprue bushings from PCS Company and a take-out robot from Yushin America. The collaboration produces a bottle opener.

Read MoreFacilities and Distribution Expansions Enable Business Shift

Edro is changing from a company focused on high quality stainless holder material, including its custom mold base manufacturing, to a full-fledged plastic molding entity.

Read MoreDemonstrations Highlight Course Opportunities and More

RJG Inc. holds multiple live demonstrations of its products on an injection molding machine in its booth.

Read MoreMetal 3D Printer Combines Laser Sintering and High-Speed Milling

Laser sinter metal powder and perform CNC machining of tooling components in the same machine.

Read MoreVacuum Devices Introduce Speed and Prevent Clogging

Cumsa introduces two vacuum devices designed to reach the desired vacuum level faster and eliminate problems caused by gas clogging in molds.

Read MoreToolroom Bed Mill Features Powerful CNC Technology

Southwestern Industries/TRAK Machine Tools showcases its three-axis bed mill and CNC technology at Amerimold.

Read MoreInjection-Blow Tooling System Reduces Labor, Improves Quality

Liberty IBM System is said to overcome long-standing limitations of injection-blow tooling.

Read MoreTechnology Combines Processes for Strong, Lightweight Components

Krauss Maffei's FiberForm technology in an injection molding machine enables the production of fiber-reinforced plastic components.

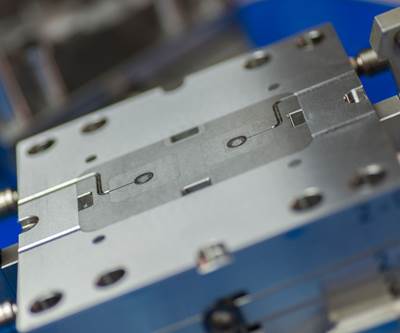

Read MoreDesign-for-Manufacture Review on Micro-Molding Operations

According to Mold Craft Inc., a design-for-manufacture (DFM) review ensures that its customers receive the highest quality molds that produce parts with close tolerances.

Read MoreContinuous Five-Axis Machining Method Reduces Tooling Costs

Makino introduces a line of five-axis continuous machines that rely on a continuous five-axis method to reduce tooling costs for die and mold machining.

Read More