Products

Clamping System Streamlines Palletizing and Clamping to Reduce Setup Time

Röhm Power-Grip Zero Point Clamping System is customizable to the machine, which enables the optimal use of the mahcine’s entire work-envelope space.

Read MoreATC Provides Ample Workpiece Storage for Unmanned Operation of Machine

The 32-position Auto Work Charger on the Mazak Variaxis i-300 five axis vertical machining center accommodates workpieces up to 13.779" in diameter, 12.401" high and weighing as much as 135 lbs.

Read MoreDual Spindle Design of Vertical Machining Center Increases Productivity

Doosan Machine Tools says its DMP 500/2SP vertical machine center is highly productive, compact and reliable.

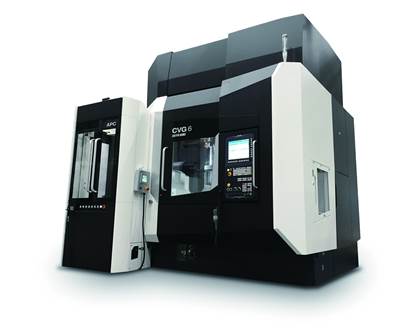

Read MorePallet Changer Increases Productivity of Grinder by Improving Spindle Runtime

The CVG series vertical universal cylindrical grinding machine parts can be loaded onto a fixture outside of the machine while the machine is running.

Read MoreHeavy-Duty Vertical Turning Center Has Optional ATC for Increased Versatility

The Puma V3800 from Doosan Machine Tools is a new generation vertical turning center with an ATC that supports Capto C6 tooling and is available for all 12 stations of the turret.

Read MoreTap Range Now Features UNC Thread Dimensions

Walter introduces UNC thread dimensions to its Paradur HT HSS-E blind-hole tap range to increase chip control and process reliability.

Read MoreHot Runner Technology Offers Complete Control of Molding Parameters

Synventive’s Synflow3 technology enables molders to slow the opening of the pin for a set distance and hold at that position until closing or alternating different moves within a cycle.

Read MoreRobots Offer Speed, Precision and a Compact Design

The SR-3iA and SR-6iA SCARA robots from FANUC offer the same intelligence and reliability that is available on all FANUC robots.

WatchAbrasive Strips Have Strong Adhesive Backing

Adhesive backing on abrasive strips from Boride tolerate wet applications.

Read MoreTouch Sensors Ensure Accurate Operations

Big Kaiser’s Base Master Red rapidly determines workpiece offsets and tool lengths.

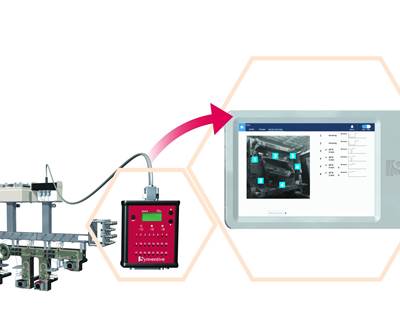

Read MoreImproved Mold Monitoring System Technology Eases Data Monitoring

Improvements to Progressive Components and AST Technology’s CVe Live Technology, which works with the CVe Mould Monitoring System, are designed to improve user convenience.

Read MoreCylindrical Head Surface on Ejector Pin Enables Secure Mold Mounting Position

Hasco Z410 ejector pins enable precise centering of individually contoured ejector or core pins.

Read More