Technology Power for Better Intelligence and Optimization at Autodesk Smart Manufacturing Celebration at Paragon D&E

Paragon D&E in Grand Rapids, Michigan, hosted Autodesk’s Smart Manufacturing Celebration last week to educate customers and fellow shops on how better intelligence for part and mold design can optimize overall manufacturing.

Paragon D&E takes relationships seriously, and that includes technology suppliers, customers and competitors. This event showcased this strategy, as the shop opened its doors not only to Autodesk and customers, but to competing shops as well. This was all in an effort to help educate the industry on the software and machining technology available to move mold manufacturing forward in a “smart” way.

One of Paragon’s key partners is Autodesk with its use of MoldFlow, Delcam tools and CAM specialty products. “We leverage our relationships on the things that we don’t do best,” Dave Muir, Paragon President says. And that is where Autodesk comes into play. Paragon gets to collaborate with Autodesk to develop its products and move industry forward to smart manufacturing.

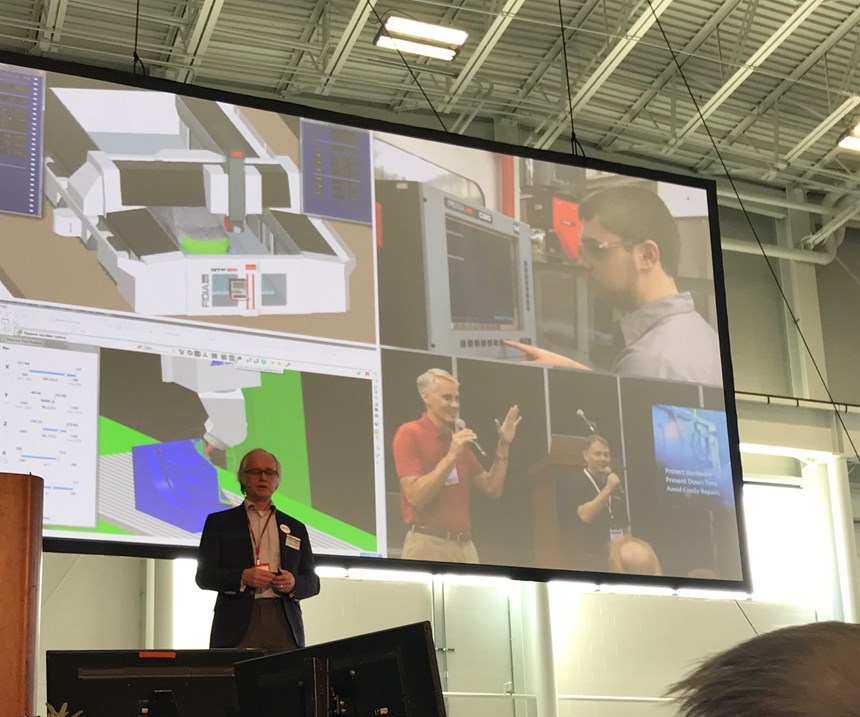

“Putting machinists in front of the screens more often to utilize the power and knowledge of Autodesk products helps to create more efficiency, and allows us to free up some of our resources to look to the future, including our new machines,” Muir says.

Challenges to smart manufacturing include staying updated with new technologies, achieving and maintaining productivity, finding or training skilled manpower, and maximizing machine utilization and machine capabilities. Automatic CAD/CAM, Moldflow Solutions (Insight and Helius), Moldflow for Design (Adviser and MF Design) and Manufacturing (Delcam) product lines can help by eliminating part recreation, taking on more difficult work, quoting more accurately, working offline, collaborating better and maximizing machine utilization.

With this in mind, Autodesk took to the tractor-trailer stage to define smart manufacturing: “Doing More Better with Less.” This involves increased automation, connected manufacturing and unleashed human talent by taking advantage of additive manufacturing, simulation, horizontal and vertical system integration, autonomous robots, IIot, big data and analytics, cybersecurity and the cloud.

When it comes to the products Autodesk offers to jumpstart a shop’s smart manufacturing journey, company representatives provided details on updates and enhancements to Moldflow (Moldflow also turns 40 this year) Insight, a complete set of advanced plastics engineering simulation tools; Helius Composite software for composite material behavior without finite element analysis (FEA); Moldflow Adviser plastic simulation tools to optimize part and mold designs to ensure molded part quality and manufacturability, and PowerMill CAM software providing comprehensive milling strategies for high-speed and five-axis machining.

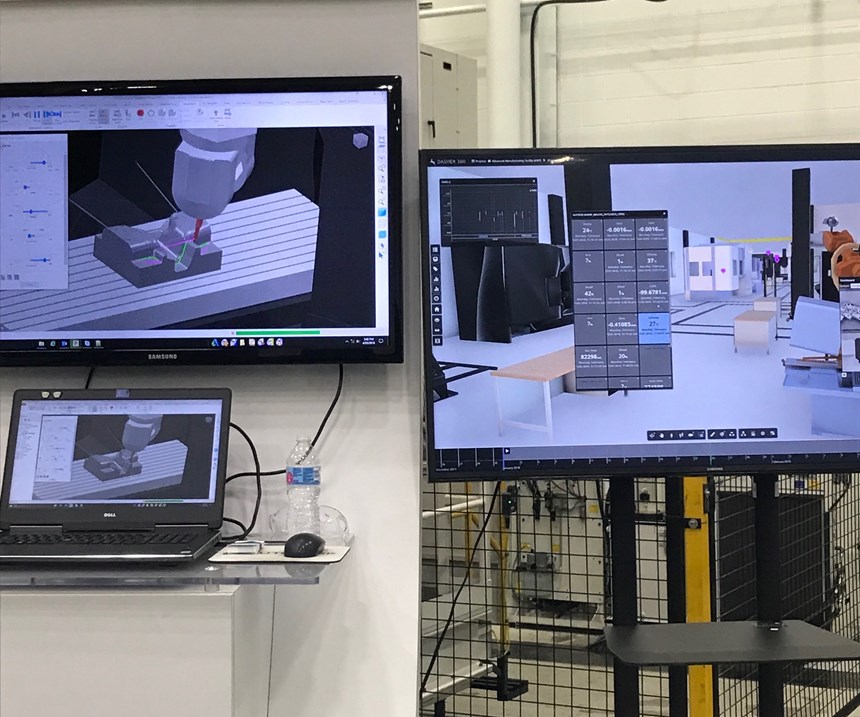

The company launched PowerMill 2019 last month and showcased its new features and functions, including a dedicated suite of strategies to help program the growing number of CNC machines that offer both additive and subtractive technology. PowerMill is capable of driving both wire-fed and powder-blown hardware with three- and five-axis machine motion. PowerMill 2019 also includes a direct interface to Autodesk Fusion Production, a cloud-based collaboration tool specializing in scheduling and tracking production, and monitoring CNC machine utilization.

Other highlights during the included a large AM subtractive modular machine (www.lasimm.edu), a robotic polishing project via Symplexity Powermill robot (www.symplexity.eu) and augmented reality via using Hololens to overlay data on a mold to polish.

Related Content

-

Five Strategies to Make Automation Affordable

Mold manufacturers can maintain their competitive edge by making smart capital investments in times of crisis.

-

5 Ways to Make Your Tooling Assets Smarter

Global mold monitoring and asset management solutions can maximize productivity and efficiency.

-

Five-Axis Graphite Mill With Automation Debottlenecks Electrode Machining

Five-axis electrode cutting enabled Preferred Tool to EDM complex internal screw geometry on an insert that otherwise would have had to be outsourced.