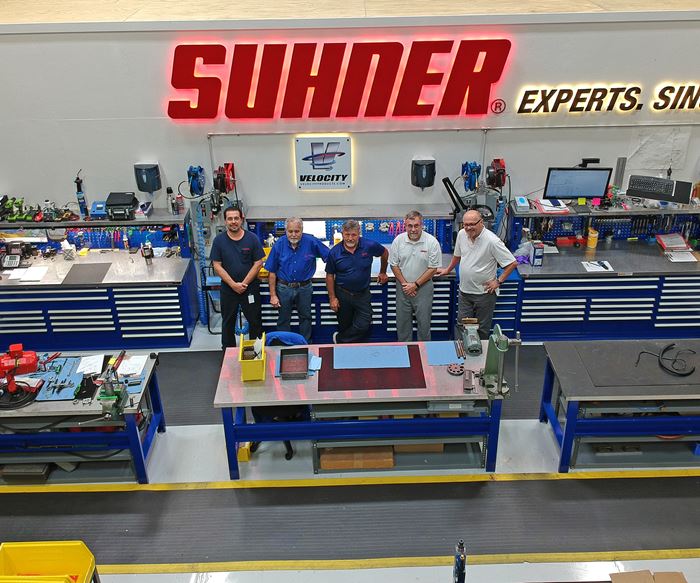

Suhner and Velocity Products Form Partnership

Suhner has teamed up with Velocity Products to maintain the SU-matic line at a consistent level of quality and functionality.

Share

Suhner has partnered with Velocity Products on the repair and maintenance of SU-matic tooling. SU-matic works closely with engineers from Okuma when designing new tools. The collaboration ensures consistent tooling performance on lathes, multi-tasking machines and machine tools.

The Velocity/SU-matic Preventive Maintenance Program offers 72-hour inspection turnaround, inspection of radial and axial play and a six month guarantee on repairs. In addition, Velocity/SU-matic tooling is guaranteed for two years; at the end of the two years, customers can send their tools to the Velocity/SU-matic repair center for inspection and return the tools to original factory specifications. The repair center is in Suhner’s new location in Rome, Georgia.

Related Content

-

Machine Hammer Peening Automates Mold Polishing

A polishing automation solution eliminates hand work, accelerates milling operations and controls surface geometries.

-

How to Achieve the Best Mold Finish

A look at factors that impact the polishability of tool steels and recommendations for obtaining a high-gloss finish.

-

Line Width vs. Depth Ratio in Laser Engraving

A laser does not produce 90-degree sidewalls. It requires a certain amount of draft in order to produce the required pattern.