Pyramid Plastics Installs Three New Industry 4.0 Injection Molding Machines

Injection molder to invest $2 million in new equipment and capabilities in 2022 to expand smart technologies, better monitor processes and data, and offer larger molding capabilities to customers.

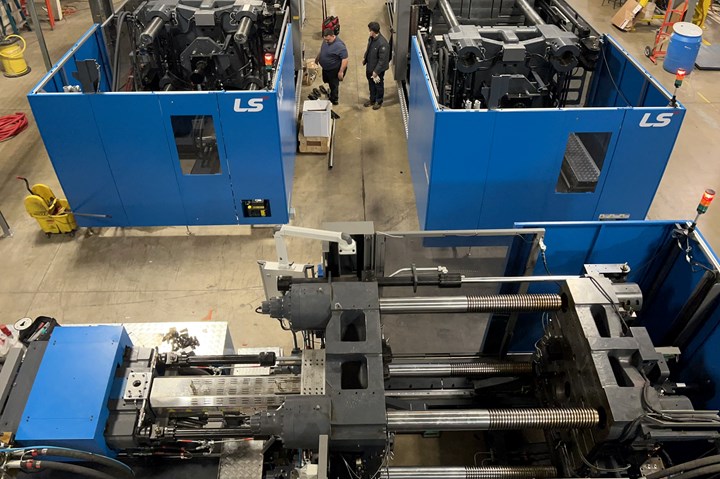

Aerial view of three new injection molding machines purchased by Pyramid Plastics this year. The company is expanding its production footprint and its capabilities to serve customers with larger molding projects. Photo Credit: Pyramid Plastics

Rockford, Illinois-based custom injection molding company, Pyramid Plastics, a division of Pyramid Molding Group, has completed phase one of its three-year plan to expand its operations with the purchase of three new injection molding machines, plus additional auxiliary equipment.

The bulk of the investment includes the purchase of three new LSMtron “the ONE” injection molding machines: two Series 1,000-ton machines and one Series 500-ton machine. All three machines are equipped with smart factory features that will help usher Pyramid’s molding operations into the realm of Industry 4.0 for more efficient, comprehensive project management.

“The smart features on these hybrid servo-hydraulic machines will allow us to monitor processes in real time and gather valuable data that we can use to improve part quality and consistency as well as reduce cycle times,” Chase McNitt, production supervisor, says. “This is the future of our industry, and we want to make sure we are maintaining and improving on industry standards. We anticipate improving cycle times as well as reducing our energy costs.”

According to Tim Peterson, president, another objective is to offer new, larger molding capabilities to customers in the automotive, medical, aerospace, defense, consumer and industrial products industries. “We have typically built and run mostly small- to mid-sized molds, and very successfully through the years,” he says. “Based on new market opportunities and the needs of our current customers, we’re evolving and expanding our resources with new, smart technologies and a larger manufacturing footprint.”

Pyramid Plastics reports that it has increased its production floor square footage by 12% to accommodate the new molding machines. In addition, a new Konecranes overhead crane—7.5 tons—has been installed to aid in production, adding to the company’s 10-ton crane already in operation. Peterson says Pyramid is also looking to build its team this year and is recruiting from within and outside the manufacturing industry.

Pyramid Plastics is a division of Pyramid Molding Group, which includes sister company Industrial Molds.

Related Content

-

Advancing Moldmaking and Plastics: Trends in 3D Printing, Automation and Sustainability

NPE 2024 showcased the latest trends and technologies in innovation, efficiency and sustainability for moldmakers and molders, featuring advancements in 3D printing, automation, design and virtual reality/augmented reality/artificial intelligence.

-

What is Scientific Maintenance? Part 2

Part two of this three-part series explains specific data that toolrooms must collect, analyze and use to truly advance to a scientific maintenance culture where you can measure real data and drive decisions.

-

VIDEO: Perspective on A.I. and Mold Design

Bill Genc of TopSolid shares his perspective on the benefits of and barriers to using artificial intelligence in mold design.