February Machine Tool Order Growth Fastest Since September 2018

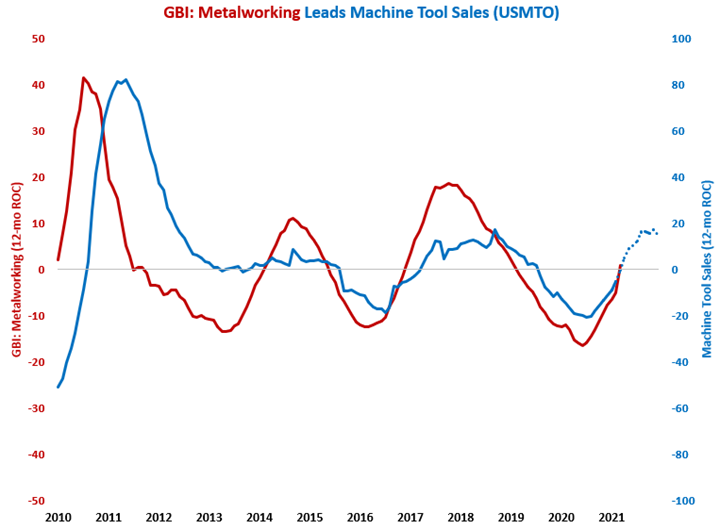

Order growth is booming as the GBI: Metalworking hits all-time highs as a result of strong growth in new orders and production at machine shops.

According the most recent Gardner Business Intelligence report, February machine tool orders were 1,969 units and $363,793,000.

Unit orders in February increased 31.0% compared with one year ago, marking the fifth month of growth in the last six months. February’s month-over-month rate of growth was the fastest since September 2018. As a result, the annual rate of contraction decelerated for the seventh straight month to its slowest rate of contraction, -5.3%, since August 2019.

In January, dollar orders increased at a nearly identical rate of 30.6%. Therefore, the average dollar price of machine tools decreased by 0.3% compared with one year ago. The annual rate of contraction in dollar orders decelerated for the seventh month in a row to its slowest rate since August 2019.

Month-over-month rates of change differed wildly among the six regions. February orders were dominated by the North-Central West and East regions.

Region Units Dollars

West 17.5% 20.7%

South Central 2.8% -18.0%

North-Central West 77.0% 107.8%

North-Central East 54.9% 76.9%

Southeast 13.8% -29.2%

Northeast 10.0% 3.3%

Compared with one year ago, the GBI: Metalworking grew 53.2%, which was the eighth consecutive month of growth and the fastest (and nearly double the next fastest ) rate of growth in the history of the GBI. The annual rate of change in the GBI grew 0.8% in March, which was the first month of annual growth since February 2019. It is clear that the annual rate of change in machine tool orders has already bottomed ahead of schedule.

Related Content

-

Hybrid Milling/Drilling Machine Reduces Total Mold Machining Time

MSI Mold Builders now squares, plus drills and taps eye-bolt holes on 50% of its tools in a single setup using a five-axis milling/drilling center with a universal spindle.

-

Three Good Reasons to Switch from Three- to Five-Axis Machining in Moldmaking

Five-axis machining technology is a great tool in the moldmaker toolbox.

-

How to Eliminate Chatter

Here are techniques commonly used to combat chatter and guidelines to establish a foundation for optimizing the moldmaking process.

.JPG;width=70;height=70;mode=crop)