Moldmakers are pushing mold component suppliers to develop more turn-key solutions and value-added services to help moldmakers serve customers more effectively and to stay one step ahead of the competition. MoldMaking Technology asked a few components suppliers to shed light on the current trends and challenges that they are seeing in the field and provide details about what they are doing to help answer customers’ needs.

Standardization Still Trending

The moldmaking industry’s need for standardized components continues to grow, pressed primarily by original equipment manufacturer (OEM) requirements for globally available products. Yet, moldmakers also support the need for standards. “Designers, moldmakers and molders have been the real innovators of mold-component standardization and continue to be so,” Bob Salhaney, senior product engineer at DME Company (Madison Heights, Michigan), says. “Instead of reinventing the wheel every time, they have approached DME for application reviews of components that they would like standardized and brought to market. This trend will continue for as long as human input is required.”

“Our moldmaker customers continue to request more and more standards that make the design and build process as ‘kit style’ as possible,” Glenn Starkey, president of Progressive Components (Wauconda, Illinois), says. “Recruitment of skilled workers is a challenge for mold builders, so anything that can be purchased off the shelf that optimizes the process is especially welcomed.”

“Our moldmaker customers continue to request more and more standards that make the design and build process as ‘kit style’ as possible.”

“Today all molds and tools are built with the use of standard mold components because it’s more economical and enables a faster mold-building time,” Rene Eisenring, general manager of Hasco America Inc. (Fletcher, North Carolina), says. “The biggest benefit will be the reduced downtime for maintenance and repairs down the road, and today’s global manufacturing environment requires the global availability of consistent standards and quality components.” Thomas Worcester, managing director of sales USA at Meusburger US Inc. (Charlotte, North Carolina), concurs, saying, “More and more moldmakers are manufacturing for clients that will potentially ship molds to another location like Mexico or Asia. The ability to support these molds as they travel throughout the world is key.”

A Need for Modifiable or Near-Standard Components Exists

Mike Hicks, vice president of DMS (Oldcastle, Ontario), says that technological advancements in plastic injection processes and mold machining processes is mainly what drives the development of new mold components. “Regarding injection molding, one example is variotherm technology, which is gaining ground in applications where the injected part must reach a high-gloss finish. There are several variotherm processes, the most common of which requires the circulation of fluids such as pressurized water or steam at high temperatures, thus requiring cooling mold components that are equipped with features suitable to this application, like fluorocarbon o-rings.” He also mentions Mucell technology that is used frequently in the automotive industry to satisfy growing demand for light-weighting parts. “Optimizing the Mucell process requires injecting plastic at high speed, which calls for optimized mold venting capabilities, hence the need for high-performing mold venting components.” He says that DMS has developed an innovative solution that can assist in resolving the most common effects of poor cavity venting. “This technology is based on a mechanical system that enables the gas to escape from a venting hole that automatically closes under the pressure of the plastic flow front,” he says. “The component can be placed inside the cavity where the filling pattern produces gas traps. Thanks to the high-venting capacity, the counter pressure of the air inside the cavity is significantly reduced, enabling faster injection speed and lower injection pressure.”

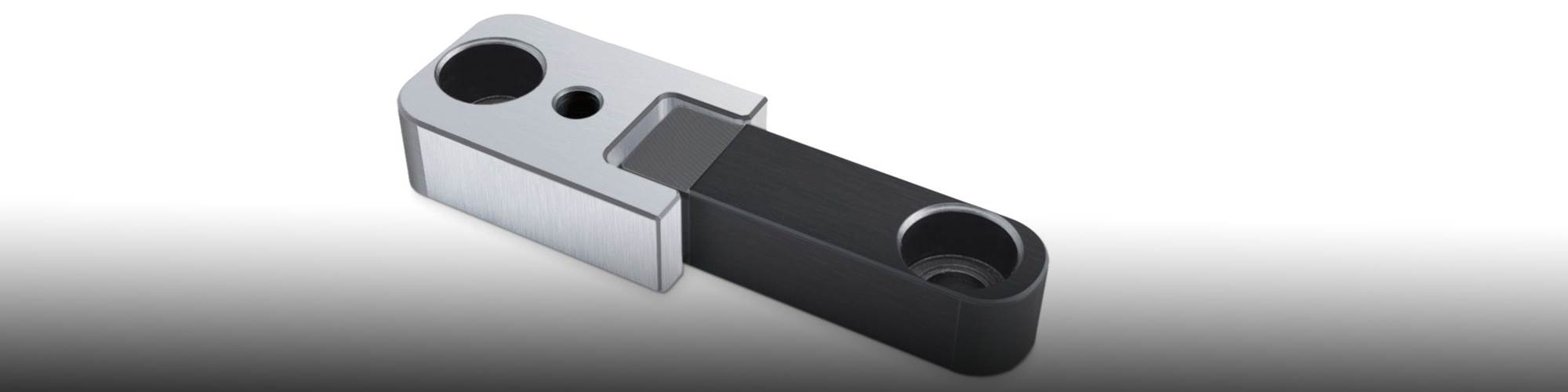

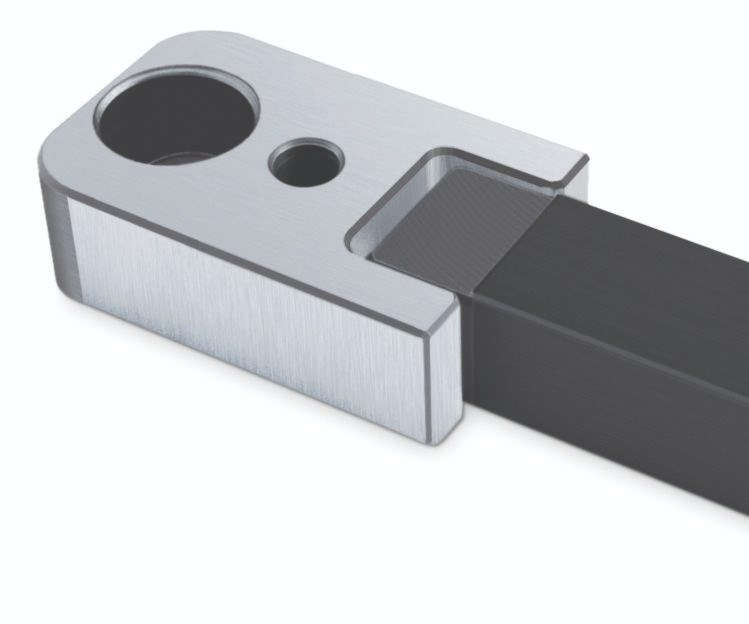

On the mold machining side, Hicks says that DMS recognizes that moldmakers are increasingly standardizing their processes to reduce costs and lead times. “For this reason, I foresee a growing demand for semi-finished components, which are easy to dowel and easily machined by the customer to suit his or her specific application. We are working on the standardization of lifters, focusing on the integration of the component in the production process. Our goal is to provide a semi-finished part together with special jigs that help optimize CNC operations by reducing time and costs.”

“Our goal is to provide a semi-finished part together with special jigs that can help optimize CNC operations by reducing time and costs.”

Kirk Visser, regional sales manager at DME, also acknowledges the growing need for modifiable or “near-standard” components that are available ready-made. “Flexibility of standards and customization are becoming more prevalent,” he says. “We are seeing more requests for mold bases that are machined complete, more hot-halves in many cases and near-standard components that have some element of customization because customers do not want to spend their time and money altering standards. They want to push this aspect down the supply chain.”

Component Performance Integral to Mold Performance

Progressive Components’s Glenn Starkey says that there is an increasing number of mold buyers who are asking moldmakers for a guaranteed number of cycles or years of performance. “That introduces an added liability to mold builders, and in turn that often brings the conversation around to what the expected component life will be,” he says. “Over the past few years, we have responded by ramping up testing of our components, which an independent lab performs. We not only test our products versus others, but we test several different versions of an item to get performance data for the use of various materials and treatments.”

In regard to materials and treatments, both Hasco and Meusburger have introduced components that are coated with diamond-like carbon (DLC). DLC is said to offer low coefficients of friction and protect against corrosion. “The introduction of the DLC coating on all our moving standard components lowers the friction without the use of any lubricant,” Hasco’s Eisenring says. “This gives our customers many benefits, including low wear, high life expectancy, prevention of the components running dry and the elimination of any risk for contamination from lubricants, which is especially important for the medical, electronics and automotive industries.” Additionally, DME plans to further expand its use of base materials and coatings that provide lubricity and reduced wear characteristics on its components, Salhaney says.

Progressive Components’s Starkey adds that moldmakers and molders are also benefitting from an increased number of standard mold actions, which help make the design, build and maintenance processes more straightforward. “Otherwise, a repair technician needs to do some detective work to comprehend how each individual custom lifter or custom side action needs to be disassembled and assembled,” he says. “Our engineering team has a hopper of ideas, and as we check off some, the team always adds more. At NPE2018 in May, we’ll introduce not only interesting gadgetry to further standardize mold building, but also advanced mold monitoring to ensure that tools are receiving scheduled maintenance for optimal performance.”

Conformal Cooling and 3D-Printed Components Increase Offerings

DME’s Bob Salhaney says that DME is looking to further assist customers by offering 3D-printed standard or custom components that can be delivered the same day or the next day. “We are rethinking what a mold is as a conveyor of plastic,” he says. “Standard mold components and designer option components are an extension of the mold frame. Components will provide more than one function, like combining latch locks with guided ejection into one component. Also, 3D printing will continue to evolve in providing accurate and efficient componentry.”

“We are rethinking what a mold is as a conveyor of plastic.”

“From a sales standpoint, conformal cooling has been revolutionary in the way it reduces cycle times and DME has a strong commitment to the advancement of this technology,” DME’s Kirk Visser says. “We are always developing new products and researching the benefits they offer to moldmakers. Our goal is full thermal control.” At NPE2018, DME will introduce new components tied to its conformal cooling line that will help solve challenges like hot spots in multiple areas of the resin flow path.

According to Dave Moore, business development manager for DME’s conformal cooling line, DME uses advanced molding analyses to review the resin properties and the ways that heat affects the mold. DME then uses the analyses to review, in turn, the ways that the mold cooling process affects the molded part as it cools and solidifies. “This shows us how resin fills the mold, how it cools and warps and how it builds up stresses in the part from the cooling process. We determine areas that will benefit from conformal cooling (because of limitations in a conventional cooling approach) and design the necessary modifications to the tool to allow use of conformal cooling technology. We review the findings with the customer and if the decision is made to move forward, we create conformal-cooled inserts that offer much greater thermal control of troubled areas in a mold that limit the process. This is accomplished through 3D metal printing that enables us to deliver cooling in ways we never could before.”

Moore says that new additive technologies have made it possible to offer a wider array of materials as well as greater sizes of printed components, and that it also has reduced the time that is required in the printing process itself. “Better accuracy and surface finish will eventually minimize the need for post-print work,” he says.

Online Tools and Simplicity Are Key

“In 2018, our customers will see many new benefits and advancements at Hasco. We introduce, on average, 15 new standard components each year, with a focus on eliminating re-work and allowing easy and error-free installation by the moldmaker,” Eisenring says. “But, we are not only improving our components, we are introducing a brand-new web portal with a powerful search tool designed to help the user build a mold base with a few clicks or find quickly what is needed in over 100,000 components.” He says that the company will add more features this year for customers in North America, like the RFQ button for requesting a quote 24/7, or drop-and-quote, where customers can drop a parts list and receive a quote automatically. “The goal is to provide simplicity to our customers around the world.”

Like Hasco, DME is also investing in its Milacron-DME eStore to provide designers with tools and information that they need to address design challenges and make the most informed decision on the right components for their application. Customers can look forward to modular components that interchange with sister components and provide easy replacement. “We have also invested in equipment to make more special-order components in-house at DME,” Salhaney says. He adds that DME works to ensure availability of CAD data for all products that is geometrically correct and along with that, global interchangeability of parts and knowledgeable global service.

Meusburger’s Tom Worcester refers to moldmakers’ approaches to building molds as the “Lego” effect because they manage a complete project from start to finish, including part approval. “This is much more than building a mold. It is also the ordering of the bases, components and hot-runner systems that make up these complete, working, manufacturing wonders: injection molds,” he says. “The tendency is to purchase as much as possible in the way of components and accessories combined with fully machined mold bases. When meeting with moldmakers, I have recognized that those focused on 750-ton molds and smaller have established the most efficient way of manufacturing these types of molds. They are focusing on their engineering and manufacturing expertise of complex cores and cavities. This is all complemented by the capabilities of the new four- to five-axis machines and enables them to finish these components directly. They have the capability to do the finish work on them in conjunction with the high-speed machining of these components. These are very complex projects with very tight timelines. Everything must meet the promised deliveries that are stated by the mold base and mold components suppliers, hot-runner systems sellers and other vendor support.”

Related Content

Think Safety: Eliminate Hazards Throughout the Shop

The tooling community is taking advantage of new products for safer mold shops and molding facilities.

Read MoreThe Role of Social Media in Manufacturing

Charles Daniels CFO of Wepco Plastics shares insights on the role of social media in manufacturing, how to improve the “business” side of a small mold shop and continually developing culture.

Read MoreMMT Chats: 4 Keys to a Successful Mold-Building Operation: Innovation, Transparency, Accessibility and Relationship

MoldMaking Technology Editorial Director Christina Fuges chats with Steve Michon, co-owner of Zero Tolerance in Clinton Township, Michigan, about the excitement of solving problems, the benefits of showing gratitude, the real struggle with delegation and the importance of staying on top of technology. This episode is brought to you by ISCAR with New Ideas for Machining Intelligently.

Read MoreSteps for Determining Better Mold Prices

Improving your mold pricing requires a deeper understanding of your business.

Read MoreRead Next

How to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read More