MMT Blog

MMT CHATS: Navigating Challenges and Innovations in Large-Scale Mold Manufacturing

MSI Mold Builders shares how to overcome large-scale mold-building challenges, sustainability efforts and future technological advancements.

WatchUnderstanding the Elusive Nature of Mold Ventilation

A personal journey of lessons learned about the challenges of poorly designed, understood and executed mold venting.

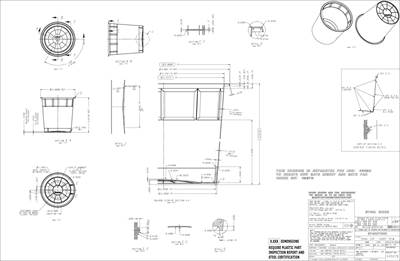

Read MoreIt Starts With the Part: A Plastic Part Checklist Ensures Good Mold Design

All successful mold build projects start with examining the part to be molded to ensure it is moldable and will meet the customers' production objectives.

WatchHow to Achieve Automated Measurement With Advanced Touch Probes and Laser Systems

A combination of lasers, probes and software help moldmakers automate in-process cutting tool and workpiece measurement.

Read MoreWhat Are Moldmakers Talking About Right Now?

The conversation encompasses smarter, more efficient and automated processes to meet the demands of mold manufacturing.

Read MoreWorking to Change the Perception of Manufacturing

Decades of mentoring helped launch an initiative to promote manufacturing careers and empower youth nationwide.

Read MoreMMT Chats: The Connection Between Additive Manufacturing Education and ROI

This MMT Chat continues the conversation with Action Mold and Machining, as two members of the Additive Manufacturing team dig a little deeper into AM education, AM’s return on investment and the facility and equipment requirements to implement AM properly.

WatchApplications Open for the 2025 SPE Mold Technologies Div. Grant and the Joseph Prischak Student Scholarship

The Society of Plastics Engineers’ Mold Technologies division is accepting applications for a $3,000 student scholarship honoring Joseph Prischak and a $5,000 educational grant program.

Read MoreHow to Achieve the Best Mold Finish

A look at factors that impact the polishability of tool steels and recommendations for obtaining a high-gloss finish.

Read MoreA Chance Encounter: MMT 30 Under 30 Honorees Unite

Imagine our surprise when two MoldMaking Technology 30 Under 30 honorees from different years crossed paths! Moments like these remind us of the tight-knit community within this specialized niche of manufacturing.

Read MoreVIDEO: Hot Runner Systems and Motion Control Advancements

Innovations in hot runner and mold motion controller technologies contribute to a more sustainable manufacturing process.

WatchSPE MTD Opens Nominations for 2025 Moldmaking Distinction Awards

The Mold Technologies Division of the Society of Plastics Engineers, Inc. is seeking nominees for its international Mold Maker, Mold Designer, Mold Repair Tech and Apprentice of the Year awards.

Read More.jpg;maxWidth=970;quality=90)

.jpg;maxWidth=970;quality=90)