MMT Blog

How to Optimize Mold Finishing

Circle segment technology requires fewer tool paths, improving surface quality and increasing cutting tool life.

Read MoreMMT Chats: Mold Builder Shares “Raw and Real” Social Media Strategy

MoldMaking Technology Editorial Director Christina Fuges sits down with Murphy Forsyth, GM – Injection Molding and Director Of Marketing for Zero Tolerance LLC in Clinton Township, MI.

WatchInnovative Technology for Your Mold Shop at IMTS 2024: Part 2

MoldMaking Technology showcases a variety of technology applications featured at IMTS 2024 this year. Find the best fit for your mold shop with software solutions to new machines and services featured in this comprehensive guide.

Read MoreBreaking Down 3D Scanning in Moldmaking

Identifying 3D scanning requirements and implementing the appropriate technology.

Read More4 Cutting Tool Challenges and Solutions

A combination of cutting tool carbide, coating and geometry helps tackle four mold machining challenges and improve cutting performance.

Read MoreIn Case You Missed It: Top August Articles

Dive into the most impactful articles from this month, featuring expert advice on guided ejection systems, mold component advancements, business growth strategies and the latest industry trends.

WatchR&D Drives Innovation and Problem-Solving at Michigan Blow Mold Builder

Mid-America Machining focuses on reshaping designs, “right weight" initiatives, continuous improvement and process refinement to enhance moldmaking efficiency.

Read MoreGlobal Tooling, Training and Motorcycle Trips | MMT Chats

Adam Nartker dives into his 22-year plastics industry journey, covering custom molding, sales, and DTI’s approach to simulation iterations. He emphasizes transparency, training for risk reduction, and lessons from offshore tooling.

WatchInnovative Technology for Your Mold Shop at IMTS 2024: Part 1

MoldMaking Technology highlights a variety of innovative applications featured this year at IMTS 2024. From software solutions to new machines and services, dive into this comprehensive guide to best equip your mold shop.

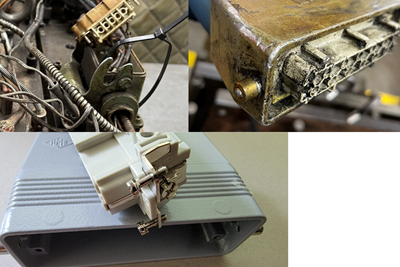

Read MoreHow to Overcome Five Common Hot Runner Cable Connection Problems

Here are some simple solutions for pushed-back or bent pins, pushed-back inserts, high amp deterioration, loose or broken latches and missing or loose ground wire connections.

Read MoreIntegrated CAD/CAM Streamlines Electrode Manufacture, Improves Quality

A focus on electrode design and automation helps toolroom improve efficiency, reduce tooling costs and deliver higher quality products.

Read MoreMake Every Shot Count: Mold Simulation Maximizes Functional Parts From Printed Tooling

If a printed tool only has a finite number of shots in it, why waste any of them on process development?

Read More.jpg;maxWidth=970;quality=90)

.jpg;maxWidth=300;quality=90)