MMT Blog

Best Practices for Mold Cleaning

Mold maintenance is a big part of the mold manufacturing process. So much so, it is part of MoldMaking Technology's tagline: Engineer, Build, Maintain. Toolrooms across the globe are faced with mold dilemnas that can often be avoided with a little TLC, namely proper mold cleaning. I came across some very useful mold cleaning tips that I'd like to share.

Read MoreAbove and Beyond the Call of Duty

For this year’s Leadtime Leader runner-up, the “ABCD” award is a key part of building camaraderie and ensuring a culture of ownership. Here are a few examples of recent winners.

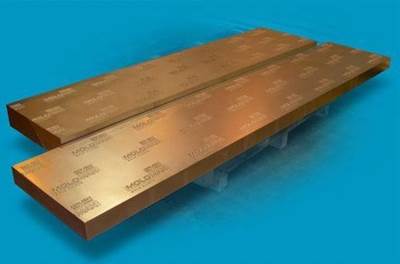

Read MoreCopper Alloys for Injection, Thermoform and Blow Molds

June 23 at 2pm EST, MoldMaking Technology is hosting a webinar that will review the strengths and weaknesses of the copper alloys used in plastic molding today. Register here.

Read MoreCavalier Tool Presented with MMT's 2015 Leadtime Leader Award

Sandwiched between the closing of the first day of Amerimold conferences and the kick-off of our casino night-themed networking party was our annual Leadtime Leader Awards presentation. I was honored to take to the podium to present Cavalier Tool & Manufacturing Ltd. President Brian Bendig with this year's Award.

Read MoreMold Making: Your Road To Success

Mold Making - Your Road To Success is an educational video targeted at youth who are considering their career choices.

WatchFace Time with Industry

The MMT Team is ready for a little face time with industry, so we are heading out to Chicago for the kick off of the Amerimold Expo tomorrow. We are excited to get the industry together once again to learn, network, share and celebrate! We hope to see you there. Visit us at Booth 731.

Read MoreThe Designer's Edge: Parting Line Vent Design

Randy believes that the way you design and cut relief channels can drastically increase your volume of venting and the amount of parting line bearing surface.

Read MoreInsight for Recruiting a Technical Workforce

With workforce development still on the minds of those in our industry, the Molding Conference, co-located with Amerimold next week, will highlight some solution sessions in its program, including one presented by New York-based molder Currier Plastics.

Read MoreStrategies for Evaluating, Maintaining Equipment

This year's Leadtime Leader award winner doesn't settle for just any test cut to evaluate a machine's capabilities. Once it does make a purchase, the shop's approach to ensuring those capabilities don't deteriorate is anything but cavalier.

Read MoreNew! Amerimold Workshops

Amerimold workshops offer a deep, concentrated dive into processes vital to the current and future success of tool and mold manufacturers. This year's workshops will feature industry experts discussing techniques for machining three-dimensional parts and for making mold maintenance profitable.

Read MoreMoldMaking Business Index for April: 49.4

With a reading of 49.4, the Gardner Business Index showed that, after five consecutive months of growth, the moldmaking industry contracted very slightly in April for the second month in a row. The annual rate of change was still growing in April, but at its slowest rate since March 2014.

Read MoreMMT's June Digital Edition Is Now Available

MMT's June issue is not only our annual Amerimold Expo show issue featuring an Exhibitor Product Showcase, it is also the issue in which we announce our Leadtime Leader Award winners.

Read More