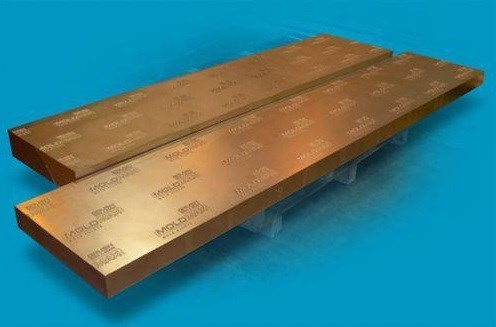

Copper Alloys for Injection, Thermoform and Blow Molds

June 23 at 2pm EST, MoldMaking Technology is hosting a webinar that will review the strengths and weaknesses of the copper alloys used in plastic molding today. Register here.

Materion Performance Alloys has worked with MMT over the years providing technical content on a variety of mold material issues, including common mistakes with copper alloy usage and copper alloy classes. That education continues tomorrow, June 23 at 2pm EST when MoldMaking Technology hosts a webinar by Materion that will review the strengths and weaknesses of the copper alloys used in plastic molding today.

Topics will include: how copper alloys differ from steel in plastic molding, how copper alloys can improve the plastic molding process and characteristics of copper alloys versus steel.

Watch the recorded webinar here.

Related Content

-

Cast Plate Aluminum Alloy is Suitable for Production Mold and Dies

Alimex Precision in Aluminum introduces its 7000 series ACP7 mold material, featuring high mechanical properties, material stability and good machinability.

-

Aluminum Plate for High-Temperature Tooling Applications

NPE2024: Ellwood Specialty Metals exhibits its EllCast 2 aluminium plate. Its strength at high temperatures, combined with high thermal fatigue resistance and hardness, makes EllCast 2 ideal for critical applications.

-

How to Machine Aluminum Molds to Enhance Efficiency and Quality

Ways to optimize the machining process to fully leverage the benefits of an aluminum mold.