MMT Blog

New Webinar: How to Use Simulation to Reduce Material and Part Cost

Register for this free webinar on reducing downstream risk through injection molding simulation software.

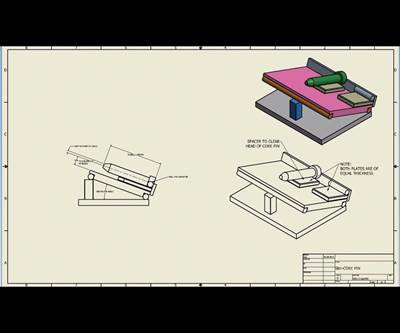

Read MoreStreamlining Roll Dimension Calculations for Mold Components

A new roll dimension calculator streamlines the use of roll pins to measure core pins, wedge blocks, shut-off surfaces or electrode details to determine the exact size of a workpiece’s angled detail.

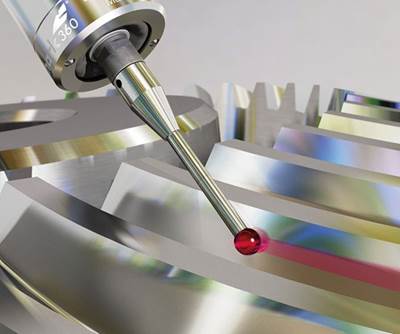

Read More2018 Technology Review and Sourcing Guide: Inspection/Measurement

MoldMaking Technology’s annual Technology Review and Sourcing Guide is an accurate, comprehensive, easy-to-read and easy-to-use use guide for researching today’s technology, equipment, products and services. The year’s latest moldmaking product developments within mold engineering/design, build and maintenance/repair are broken down into 10 sections, including inspection/measurement.

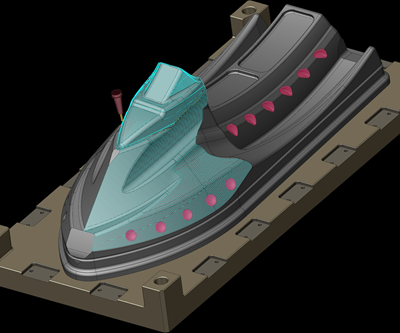

Read MoreHow to Advance Molding Undercuts with Collapsible Core Design

A new flush-style collapsible core design might help to overcome objections to using the technology and advance the molding of undercuts.

Read More2018 Technology Review and Sourcing Guide: Machining

MoldMaking Technology’s annual Technology Review and Sourcing Guide is an accurate, comprehensive, easy-to-read and easy-to-use use guide for researching today’s technology, equipment, products and services. The year’s latest moldmaking product developments within mold engineering/design, build and maintenance/repair are broken down into 10 sections, including machining.

Read MoreChoosing Between Solid Carbide and Indexable Cutting Tools

Criteria like machine tool spindle power, workpiece geometry and material, CAD/CAM for CNC programming and fixturing drive rough milling cutter selection.

Read More2018 Technology Review and Sourcing Guide: Mold Components

MoldMaking Technology’s annual Technology Review and Sourcing Guide is an accurate, comprehensive, easy-to-read and easy-to-use use guide for researching today’s technology, equipment, products and services. The year’s latest moldmaking product developments within mold engineering/design, build and maintenance/repair are broken down into 10 sections, including mold components.

Read MoreEDM Machine Size is Paramount

The constant need for larger, more efficient machining capability pushed Extreme Wire EDM Services to approach GF Machining for a larger wire EDM solution.

Read MoreDecrease Cycle Time with More Advanced Moldmaking Equipment

Today’s improved machine tools, tooling, workholding and CAD/CAM technology have made substantial gains over the last ten years. These advances allow shops to reduce the time it takes to machine cavities, cores, inserts and other components.

Read MoreA CAD-for-CAM Toolbox Helps Moldmakers Design Better Molds

An important CAD function that a CAM package should offer moldmakers is a set of specialized CAD-for-CAM tools that focus on the machinist’s needs after the machinist opens the part file.

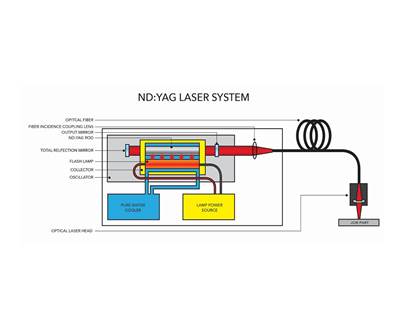

Read MoreChoosing the Right Beam Source for Your Laser-Welding Operation

Fiber laser technology is here, but is it the right solution for your operation?

WatchWhy a Decrease in Consumer Savings Is Good for Consumer Products

Consumer products goods companies should expect to do well in 2018.

Read More