A Quality Plan is a document, or several documents, that together specify quality standards, practices, resources, specifications, and the sequence of activities relevant to a particular product, service, project, or contract. Quality plans should define a method for measuring the achievement of the Quality objectives. Quality objectives are measurable goals relevant to enhancing customer satisfaction and are consistent with the Quality policy. These objectives are initially established when planning your Quality Management System (QMS) and redefined in management reviews as needed. Examples can include goals to improve on-time delivery, defects, or scrap.

It is the responsibility of top management to ensure that a QMS is implemented and properly maintained. They should undertake QMS planning to ensure:

- The on-going development of the QMS to meet the requirements

- The on-going development of policies and objectives

- Processes and resources exist to identify characteristics at different stages

- The ability to proactively review and improve the QMS

- Verification activities, determine criteria for acceptability

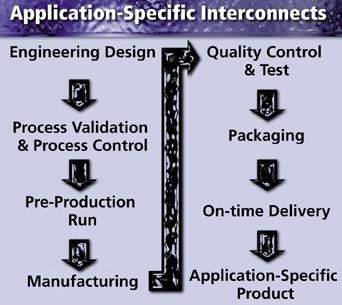

Each department manager should develop and maintain a process map, flow chart, quality plan, operating procedure, etc., that show the workflow of the department as well as referencing evidence of compliance with the requirements of the QMS. If your organization outsources specific processes or requires strict control over its supplied product, it might be appropriate to establish a quality plan. This defines the quality practices, resources, and activities relevant to the product to be designed or supplied while also establishing how to meet the requirements for quality. The quality assurance requirements are then implemented through the use of this plan in conjunction with the manufacturer’s quality manual and operating procedures.

This plan further includes, but is not limited to, the following key activities, as appropriate, in meeting the specified requirements for the products, projects, or contracts. The preparation of the quality plan might include:

- The identification of processes, resources, and skills to achieve quality

- The identification of suitable verification criteria at appropriate stages

- Demonstrating compatibility of design, production, inspection, and testing

- The clarification of standards of acceptability for all features per requirements

- Details of calibration of any special measuring or test equipment to be used

- Applying Total Quality to Sales (sales/customer service in need of quality training)

Related Content

Making Mentoring Work | MMT Chat Part 2

Three of the TK Mold and Engineering team in Romeo, Michigan join me for Part 2 of this MMT Chat on mentorship by sharing how the AMBA’s Meet a Mentor Program works, lessons learned (and applied) and the way your shop can join this effort.

Read MoreDynamic Tool Corporation – Creating the Team to Move Moldmaking Into the Future

For 40+ years, Dynamic Tool Corp. has offered precision tooling, emphasizing education, mentoring and innovation. The company is committed to excellence, integrity, safety and customer service, as well as inspiring growth and quality in manufacturing.

Read MoreTop 10 Topics to Cover During an ISO 9001 Manufacturing Audit

Take a look at this practical hands-on approach to conducting a quality audit.

Read MoreThink Safety: Eliminate Hazards Throughout the Shop

The tooling community is taking advantage of new products for safer mold shops and molding facilities.

Read MoreRead Next

Solutions for Managing the Plastics Supply Chain

As our 2016 Keeping Up with ISO column comes to a close, I thought I'd revisit some archived content on the subject, which offers solutions for properly managing the plastics supply chain to help improve the OEM's total cost of manufacturing.

Read MoreCreating an Effective Supplier Management Scorecard

Keeping Up with ISO columnist, Lewis Yasenchak wants to help moldmakers measure performance metrics across their supply chain with this quick-read. How often do you check your supplier management scorecard?

Read MoreKeeping Up with ISO: Moving to ISO 9001:2015 Requires a Top-Down Approach

Implementing ISO guiding principles to govern every activity within a moldmaking or molding facility is essential to properly managing the supply chain. This new column will share knowledge, highlight opportunities and spotlight rewards of the ISO 9001: 2015 revision.

Read More