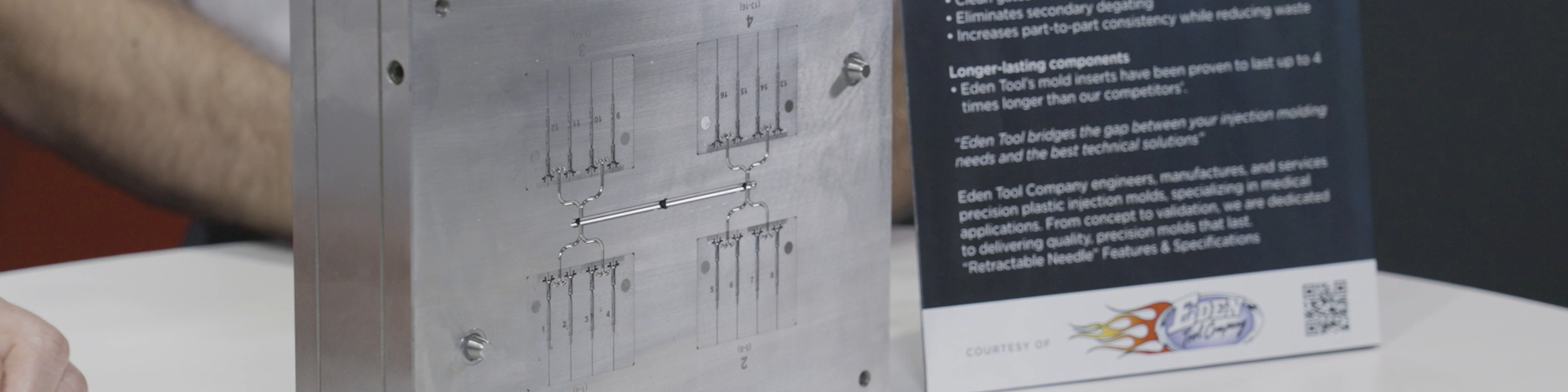

At Eden Tool, predictable manufacturing is at the core of everything they do. Here, Dave Tomic, President of Eden Tool and Eden Manufacturing, uses a medical mold project for a retractable needle to explain predictable manufacturing and how to implement this principle in any shop.

He discusses the critical part features and challenges of this SPI Class 101+ tool, its mini-tunnel gate and longer-lasting components.

Also, tune in to find out who won the Mike Eden Mold Builder Scholarship.

Chapters:

0:00 Introduction

0:40 Explaining predictable manufacturing

1:00 Predictable manufacturing applied to a retractable needle mold

1:51 What technology is key to predictable manufacturing?

2:06 Mike Eden Mold Builder Scholarship prize winners

For more video content from MMT, visit https://www.moldmakingtechnology.com/videos

Related Content

-

The Secrets to Hard Milling Success

The Secrets to Hard Milling Success

-

It Starts With the Part: A Plastic Part Checklist Ensures Good Mold Design

All successful mold build projects start with examining the part to be molded to ensure it is moldable and will meet the customers' production objectives.

-

Laser Welding Versus Micro Welding

The latest battle in finely detailed restoration/repair of mold materials.

.png;maxWidth=300;quality=90)