Photo Credit: (top left) Hexagon Manufacturing, (top right) Hasco, (bottom left) Tungaloy and (bottom right) Walter.

New technologies have been launched for moldmakers over recent months, including modular sorting systems, monitoring platforms for injection molders, indexable milling cutters and more. Below, MoldMaking Technology has compiled previews of each new product.

To view the full product post, click the linked titles, or find them in the “New Tech” section of the website. In addition, learn new ways to enhance your moldmaking capabilities by reading our recent hot runner and mold components technology roundup.

Photo Credit: Mold-Masters

Mold-Masters’ SmartMOLD is a cloud-based software platform dedicated to providing real-time data to drive injection molding innovation. Process data is collected from sensors embedded within the injection mold which offers feedback and insights for enhanced productivity.

According to the company, SmartMOLD is the first step toward predictive and autonomous capabilities. In addition to collecting sensor data, SmartMOLD software offers performance tracking, downtime tracking, scrap tracking, maintenance reminders, alerts, reporting, analytics, mold info, document storage and more. Although SmartMOLD is focused on the mold, it also has the potential to pull data from injection molding machines. SmartMOLD is also compatible with any brand of equipment.

Tungaloy’s new AddForceBarrel indexable profile milling cutters feature barrel-shaped cutting edges that are designed for efficient semi-finish machining of 3D surfaces.

Based on the design of the TungMeister barrel shape milling head series, which were developed for efficient finish profiling of 3D surfaces such as complex dies and turbomachinery components in five-axis milling operations, Tungaloy’s AddForceBarrel offer an indexable insert solution.

AddForceBarrel uses inserts whose cutting edges have a large-radius arc of either 20 mm (.787″) or 30 mm (1.181″), designed for semi-finish profiling of 3D surfaces. AddForceBarrel is said to provide greater engagement area between the cutting edge and workpiece compared to conventional ballnose end mills. Greater engagement area enables larger stepovers, which improves metal removal rates for reduced number of cutter passes and cycle times.

Hasco now offers the round locating unit Z083 for the precise, offset-free centering of injection molding tools and mold inserts. The unit also locks to prevent transversal forces in the mold.

The one-sided DLC-coated locating unit is mounted in the mold via the center axis in order to compensate for differing heat expansion in the two mold halves. Hasco says it can also be screwed on either from the mold parting surface or from the back and is easy to carry out through the circular geometry. A two-sided thread in the fixing bore holes simplifies dismantling for maintenance.

Offered over a range of dimensions (10-42 mm), a uniform clearance of 0.002-0.012 mm is ensured across all sizes.

MC Machinery Systems’ new ASTES4 High Speed Advanced is a modular sorting system that can reportedly cut sort times in half, reduce labor costs, improve throughput and eliminate bottlenecks.

Photo Credit: MC Machinery Systems

The new system is a solution for fabricators facing worker shortages and bottlenecks resulting from the increased productivity of higher-volume fiber lasers. The high-speed modular sorting solution is said to maximize the productivity and efficiency of downstream operations.

The ASTES4 High Speed Advanced features multiple tools on each head, including a single suction cup tool, a magnet tool (featuring two sizes), a multi-suction cup tool, a dual-oval suction cup tool and an out-of-center tool for small or heavy parts that require two lifting points.

Photo Credit: Hexagon Manufacturing Intelligence

Hexagon’s Manufacturing Intelligence division announced the HP-L-10.10, a non-contact laser sensor for CMMs that is said to offer manufacturers the ability to perform dimensional measurements at comparable accuracy to tactile probing and inspects almost any surface in a fraction of the time.

The HP-L-10.10 sensor uses Hexagon’s latest cross-platform laser line scanning technology to offer similar repeatability and performance compared to tactile measurements executed on the same CMM. Furthermore, it can reportedly measure 600,000 individual points per second with a probing form error of just 8μm, rapidly capturing a complete high-resolution digital representation of a part that is valid for both surface and detailed feature inspection. The HP-L-10.10 is said to be seven times faster than its predecessor and introduces high precision scanning.

Photo Credit: Exact Metrology

Exact Metrology, a division of In-Place Machining Company and a comprehensive 3D metrology service provider and hardware sales company, now offers portable, high-performance laser tracker technology with the Leica Absolute Tracker AT960.

The AT960 is a robust laser tracker that is said to fit in a single flight case. It offers high-speed dynamic measurement and is said to be a complete solution for six degrees of freedom (6DoF) probing, scanning and automated inspection as well as reflector measurement. The AT960 laser tracker can reportedly be powered up in minutes and features wireless communication and a battery operation option, as well as integrated technology that reduces setup time.

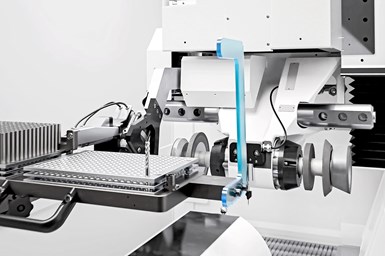

Walter’s latest addition to its comprehensive machine lineup is the compact Helitronic G 200 tool grinding machine. In a floor space of less than 24.8 square feet, the Helitronic G 200 offers grinding and re-sharpening of rotationally symmetrical cutting tools ranging from 1 to 125mm (0.039" to 4.92") in diameter with a grinding wheel up to 150mm (5.91"). The Helitronic G 200 can reportedly accommodate a maximum tool length of 235mm (9.25") and a tool weight of up to 12 kg (26.45 lbs).

The ergonomic design integrates a swiveling multifunction touch panel with a 21.5" monitor, facilitating easy operation and accessibility to the working area. A low-vibration solid mineral cast bed and C-frame construction offers high damping capabilities and thermal stability, which Walter says results in maximum grinding precision. According to Walter, the linear X, Y and Z axes are built to high-quality standard, and the rotating A and C axes are equipped with torque motors to provide an long lifetime with minimum service effort.

.png;maxWidth=300;quality=90)