Understanding Electric Valve Gates

What the right electric valve gate system means to the moldmaker and his customers.

Hot runner valve gating is a technology that has been available for many years; however, until recently, there have only been two options for pin actuation: hydraulic or pneumatic. Both types of valve pin actuators come with their own advantages and disadvantages making the decision a matter of personal preference.

Pneumatic actuators are cleaner, require less maintenance, and are more energy efficient than their hydraulic counterparts. However, they need to be much larger to produce the same amount of force as hydraulic actuators and because of the compressibility of air they tend to have slower and less consistent response times. The choice between hydraulic and pneumatic has always been a compromise of what attributes were most important to the specific application.

A new electric option has emerged offering a variety of benefits to both the moldmaker and the molder. There are a number of electric valve gates on the market today. All of these have the obvious advantages over fluid power for cleanliness and energy efficiency. Many of them have additional benefits as well. It’s important to understand the capabilities of the various options available to you in order to choose the system that best fits your needs.

Savings for Moldmakers

To the moldmaker an electric valve gate can offer savings during design, build and the initial samples. Hydraulic and pneumatic actuators require either gundrilled or separate plumbing lines connecting the open and close ports of actuators to the hydraulic or pneumatic disconnects on the exterior of the mold. Gundrilling these lines can be expensive and using plumbing requires large clearance channels in the plates for the plumbing to run. The wires for an electric actuator are far smaller requiring much narrower channels. This adds flexibility when designing the channels to exit the connections and results in much less machining to the plates, reducing machining time and protecting the structural integrity of the tool.

Installation of the hot runner is simplified because all plumbing is eliminated as well as the need to bleed the actuators as required with hydraulics. Initial sample times can also be reduced. Electric actuators are repeatable from the very first shot—not requiring time for the hydraulic fluid temperature to reach equilibrium. Some electric valve gates offer the ability to easily adjust the pin closing position right from the controller while the mold is in the press. This eliminates the need to pull the mold after first shots, adjust the pin height settings and have subsequent samples if the initial pin settings were not perfect.

Advantages to Molders

As beneficial as electric valve gates can be for moldmakers, they can offer even more for their customers, the molders. Electric valve gates are inherently more responsive and more repeatable than hydraulics or pneumatics, increasing shot-to-shot and part-to-part consistency. They are also extremely clean, quiet and energy efficient.

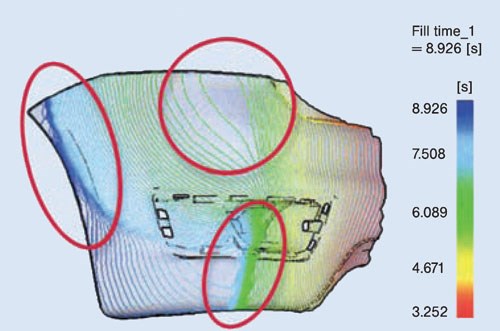

Some of the electric valve gated systems available today work similar to traditional valve gates, only opening and closing the pins with a preset stroke. Others offer the molder complete control over the pin’s opening and closing speeds, acceleration and stroke, resulting in greater process control. This additional control over the movement of the pins can help the molder process away gate defects and control the balance of fill.

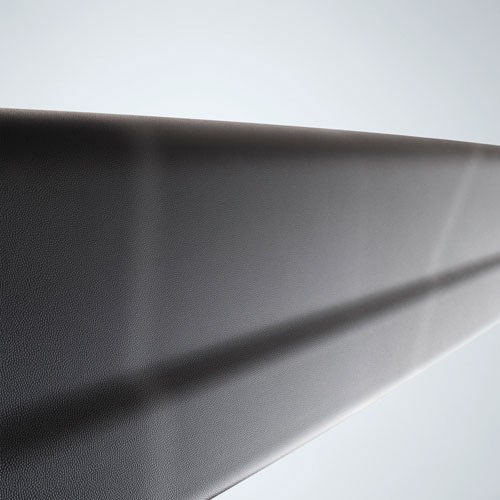

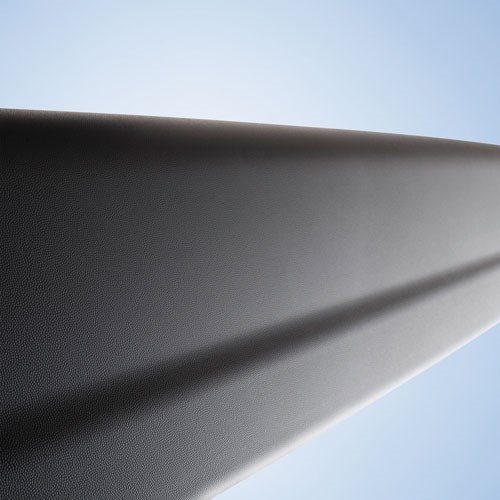

Another advantage of being able to control the speed of the pins comes when cascade filling. Cascade filling with conventional valves gates often results in flow marks caused by sudden acceleration and stagnation of the flow fronts. These flow lines are the result of pressure building up in the hot runner system behind the gates that are not opened at the start of fill. Once the flow front reaches these gates and they are opened, there is an abrupt release of pressure into the cavity. This causes the existing flow front to drastically accelerate near the newly opened gate and stagnate in areas away from the newly opened gate. Slowing down the initial opening of the delayed valve pins prevents this surge of material that results from sequencing with on/off style valve gates, thereby eliminating these flow marks.

Summary

It is important to remember that not all electric valve gates have the ability to control the speed of the valve pin’s movement. Some act as simple on/off style gates with the cleanliness, energy saving and repeatability advantages of all electric gates, but not advanced pin control capabilities. Some others offer the advanced pin control abilities, but are tied into a plate actuation system that does not allow the molder individual pin control. These plate-actuated electric valve gate systems don’t offer any control over balance or the ability to sequentially fill. When choosing an electric valve gate you should first take the time to define your needs and those of your customer and then make sure to choose a system that properly meets them.

Related Content

Treatment and Disposal of Used Metalworking Fluids

With greater emphasis on fluid longevity and fluid recycling, it is important to remember that water-based metalworking fluids are “consumable” and have a finite life.

Read MoreHow to Eliminate Chatter

Here are techniques commonly used to combat chatter and guidelines to establish a foundation for optimizing the moldmaking process.

Read MoreMachining Center Spindles: What You Need to Know

Why and how to research spindle technology before purchasing a machining center.

Read More6 Ways to Optimize High-Feed Milling

High-feed milling can significantly outweigh potential reliability challenges. Consider these six strategies in order to make high-feed milling successful for your business.

Read MoreRead Next

Electric Valve Gates Deliver Higher Speed and Precision

For productivity increases, faster speeds and more control over material flow, this hot runner technology is worth a look for cleanroom applications.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read More